7

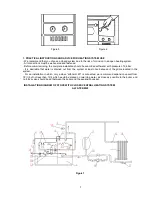

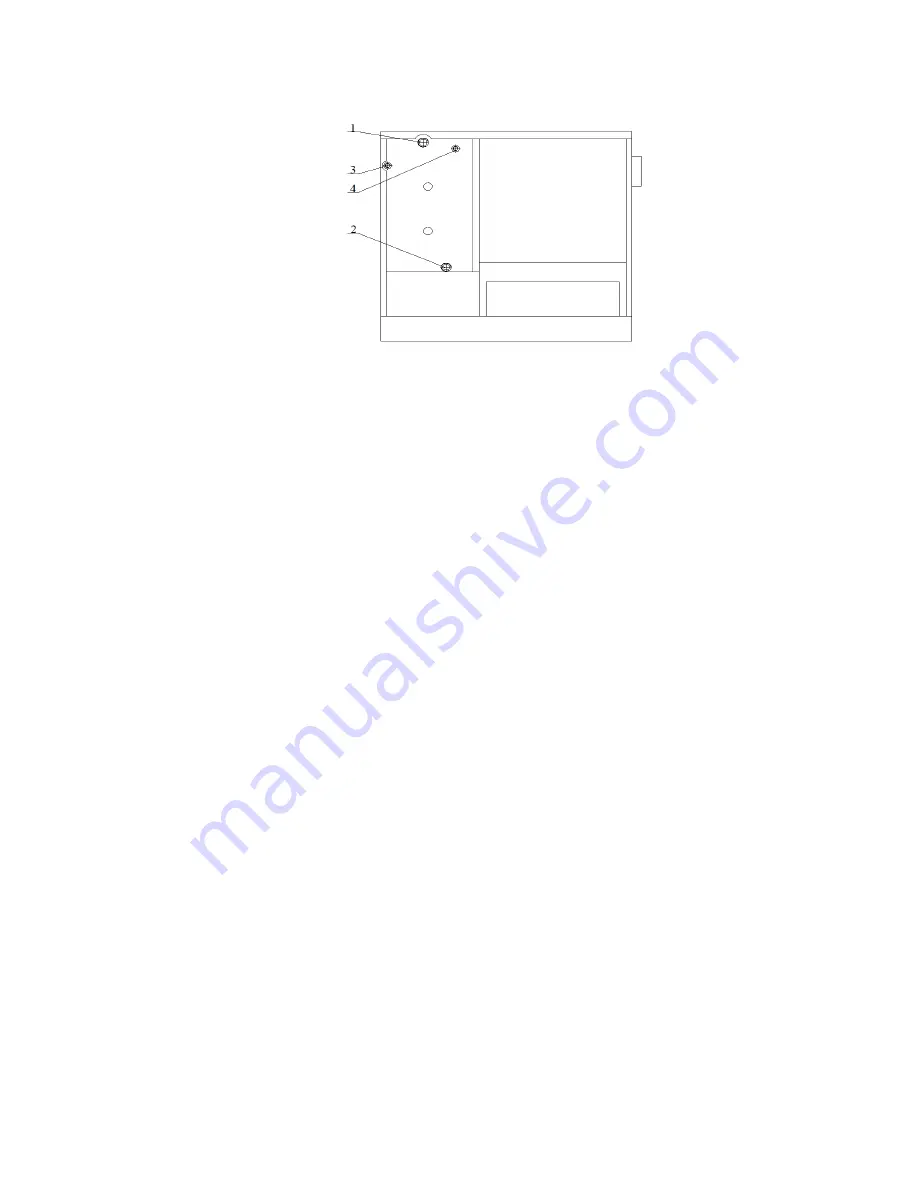

The back of the boiler and connections are shown in Fig. 4 where:

Figure 4

- Item 1 is an R1" connection with an outer thread for the flow pipe,

- Item 2 is an R 1" connection with an outer thread for the return pipe,

- Item 3 is an R1/2" connection with an inner thread for installation of the thermal valve safety pipe,

- Item 4 is an R1/2" connection with an inner thread for safety valve installation.

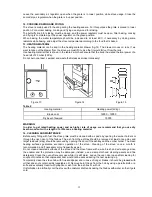

6.1 DISCHARGE AND RETURN LINE (fig.4 pos.1 and 2 and fig.7 and fig.8 pos.3 and 10)

The outlets of the discharge and return water of the boiler are 1" and they must not be reduced, that is,

narrowed up to the first bifurcations. Use steel pipe 1" or copper pipe with external diameter F28mm. (or bigger

diameter).

When performing the installation, strictly pay attention to the pipe slopes which should be 0,5% (5mm. per

meter of pipe) and to the system venting (boiler, pipes, radiators).

On the discharge line you may set thermal-manometer although thermometer and manometer are mounted on

the front side.

Set a “by-pass” on the return line with a pump, expansion vessel and valve for filling and draining the system.

When mounting the pump, pay attention to the pump direction.

Warning:

Make a "by-pass" only if there are conditions for so called gravitational heating.

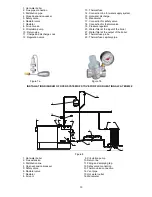

. 6.2 THERMAL VALVE WITH BUILT-IN THERMAL PROTECTION AND ADDITIONAL ELEMENTS FOR

CONNECTION

To install thermal valve it is necessary to purchase and install:

1. Thermal valve with built-in thermal protection type 544, 1/2", product Caleffi (Fig. 7a) and Fig. 7, Item 13.

2. Slope pressure regulator with manometer 1/2", the same or similar as shown in Fig. 7b and Fig. 7, Item 19.

3. Filter for cold water at the input of the water supply to the thermal valve, Fig. 7, Item 20

4. Filter for hot - boiling water intake of the boiler and water outlet of thermal valve, Fig. 7, Item 21.

Note:

These components are not included with product for central heating you bought!

Installation of thermal valve with built-in thermal protection (Fig. 7, Item 13 and Fig. 7a) with additional

elements ensuring safe operation, such as pressure regulator (Fig. 7, Item 19 and Fig. 7b). Water filter on the

boiler intake (Fig. 7, item 20) and water filter on the boiler outlet in closed central heating system is

MANDATORY. This specially refers to a closed system, when the radiators are submerged and where in case

of termination of the pump operation for any reason, the water temperature in the boiler rapidly increases and

overheating occurs very quickly.

In the open central heating system, installation of thermal fuse is not mandatory.

6.2.1 THERMAL VALVE WITH BUILT-IN THERMAL PROTECTION (Fig. 7, Item 13 and Fig. 7a)

Thermal fuse is installed near the stove, depending on the available space. It can be installed in any position.

You should take into account the direction of cold water intake and hot water outlet from the boiler which is

clearly marked on the valve body.

The thermal fuse probe (Fig. 7, Item 22) is best to place in the thermal valve connection (Fig. 7, Item 18). It can

be placed on the discharge - distribution pipe (Fig. 7, Item 3) but at a distance from the boiler of 500 mm the

most or at the highest point of the boiler before the exhaust pipes.

Seal it with hemp or other sealing material by tightening.

Fig. 7 shows the thermal valve installation diagram.