20

A2M 200

6. MAINTENANCE

6 . 1 STATE OF MAINTENANCE

The maintenance operations must be performed with the

machine in the conditions described at “state of the machine”

in the tables 6.6-A and 6.7-A

6 . 2 SPECIAL CAUTIONS

During the maintenance or repair operations is suggested to

proceed as follows:

•

Before starting any operation place a sign “machine under

maintenance” in a well visible position

•

Do not use solvents or flammable materials

•

Do not disperse into the environment lubricating liquids

that have ozone harmful propellents.

•

Do not step on the machine parts, because they have

not been projected to sustain the weight of persons.

•

Once all the operations are finished, replace any

protections or shields you removed or opened

6 . 3 CLEANING

The machine structure is simple and robust therefore the

mechanical parts do not require any special maintenance.

It is advisable to follow the rules listed below:

•

Regularly remove glue or other residues from the V-nail

head and from the upper part of the driver blade;

•

Always keep the V-nail magazine clean & without

residues.

•

Remove any residue from the V-nails guide “L” shaped

support.

Do not use water to clean the machine, otherwise metallic

parts may oxidise.

Table 6.4-A

Maintenance

Description

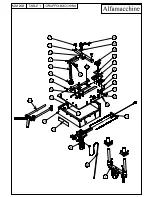

V-nail driver blade

Replacement every 1.000.000 V-nails driven

Movable parts lubrication

Lubricate the driver blade every 200 working hours

V-nail claw heads

Replacement every 5.000.000 V-nails shot

“L” shaped supports (V-nails guide)

Replacement every 5.000.000 V-nails shot

6 . 4 ORDINARY MAINTENANCE

The following operations must beperformed at the times

indicated below. Not observing the following instructions

exonerate the Producer from any responsibility regarding

the warranty.

The operations described below, even if simple, must be

executed by qualified staff.

The scheduled ordinary maintenance includes overhauls,

checks and interventions that will help prevent stops and

breakdowns, & keep the system working properly.

•

Lubrication state of the machine

•

Greasing state of the mechanism of clamp and driver

blade movement

•

Wear and tear parts state