6

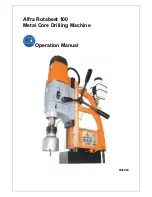

Switching on and off.

•

Check connecting line and plug on damages first!

•

Push button MAGNET ON, in order to initiate the magnet and the

magnetic adhesion is guaranteed.

•

When working on walls and ceilings, safe machine with safety belt (f).

•

Push the button MOTOR ON to start the Motor.

•

The magnet foot now reaches its maximum magnetic adhesion! In case

of a damaged magnet, the motor won´t start.

•

To switch off machine proceed in reverse order : MOTOR OFF and

then MAGNET OFF!

Change of tools

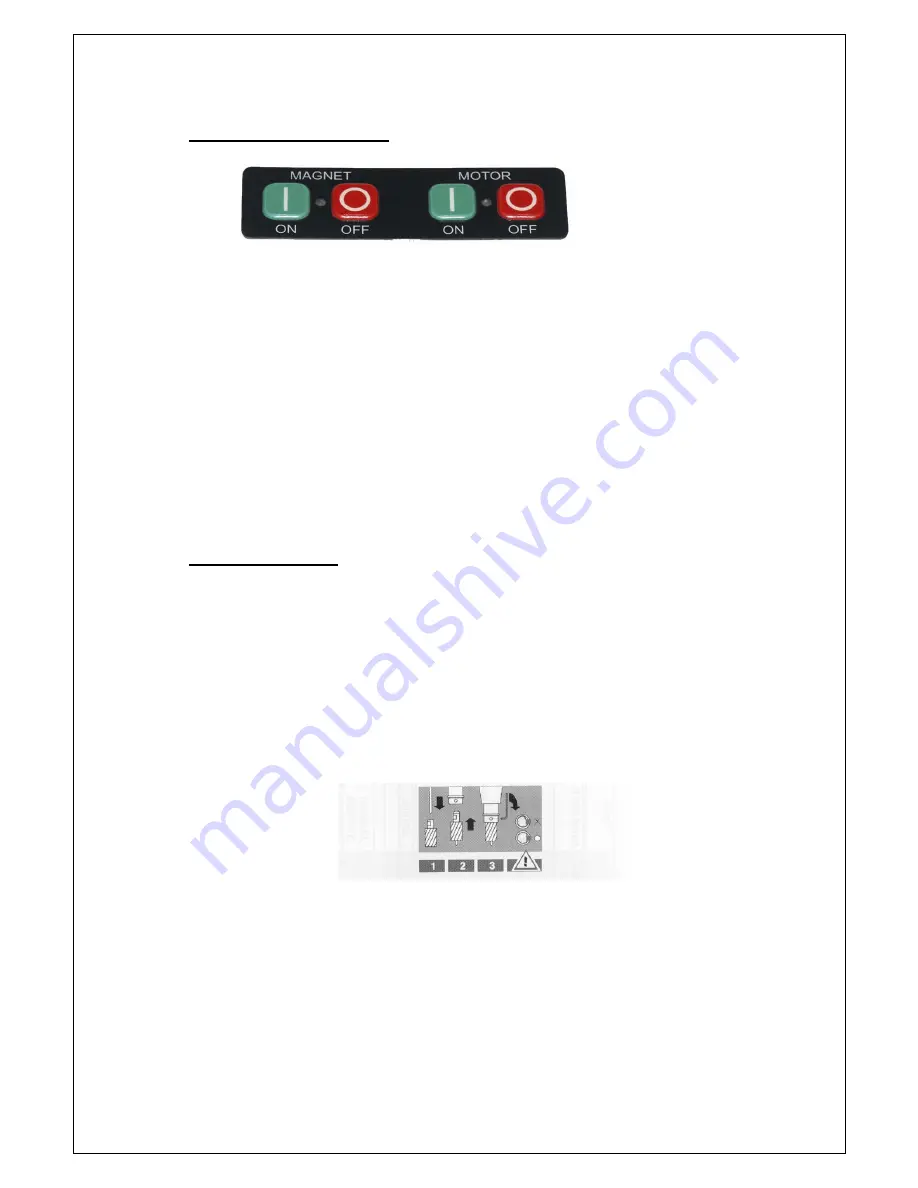

How to work with annular cutters ( Weldon shank)

•

Mount Tool Holder AMK 3 in arbor.

•

Push ejector pin (center pin) through head of annular cutter.

•

Mounting of Rotabest Cutter according to drawing. Setscrew must be

positioned in the center of the lateral flat side of the Weldon shank. Fix

tightly.

How to work with TCT Core Cutter Type AL

Mount TCT Core Cutters with keyway (2002...050) on Tool Holder AL 3

(20230) and fix setscrew tightly.

Adjustable magnet foot:

For better positioning release clamping lever (H). Now the machine can be

swiveled 30° left or right, resp. move 10 mm for- and backwards. When

using cutters larger than 80 mm the magnet foot must be in the home

position.