17

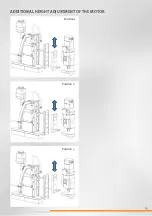

hOw TO wORk wiTh TwisT dRiLLs

1. Twist drills with MT4 shank can be inserted directly into the arbor.

2. For a maximum enlargement of the stroke when using twist drills, drill chucks and tapping

attachmentsthe motor can be continuously adjusted on the slide by loosening the Allen screw.

TApping

With a tapping attachment with MT4 shank, threads up to M 42 can be tapped.

cLeAning And cARe

• Clean the outside of the motor with dry compressed air.

• Check connecting lines on damages.

• Clean and grease sliding surfaces regularly. Should lateral play arise by wear of the dovetail guide

then this can be evened out by adjusting the laterally positioned set screws.

• After the work is finished we recommend to store the Metal Core Drilling Machine in the transport

case in a lying position.

mAinTenAnce And RepAiR

• Maintenance, check and repairs are only to be made by electronics specialists according to the valid

regulations of the respective country.

• The Metal Core Drilling Machine ALFRA ROTABEST should be serviced after appr. 250 hours running time

by our ALFRA workshop or appointed dealers.

• The gear oil (Lubcon, Turmogearoil PE 150 300ml) should be exchanged as well as the brushes after that

running time.

pull plug prior to cleaning to avoid injuries by unintentional switching on of the machine.

!

Only use genuine ALFRA spare parts.

!