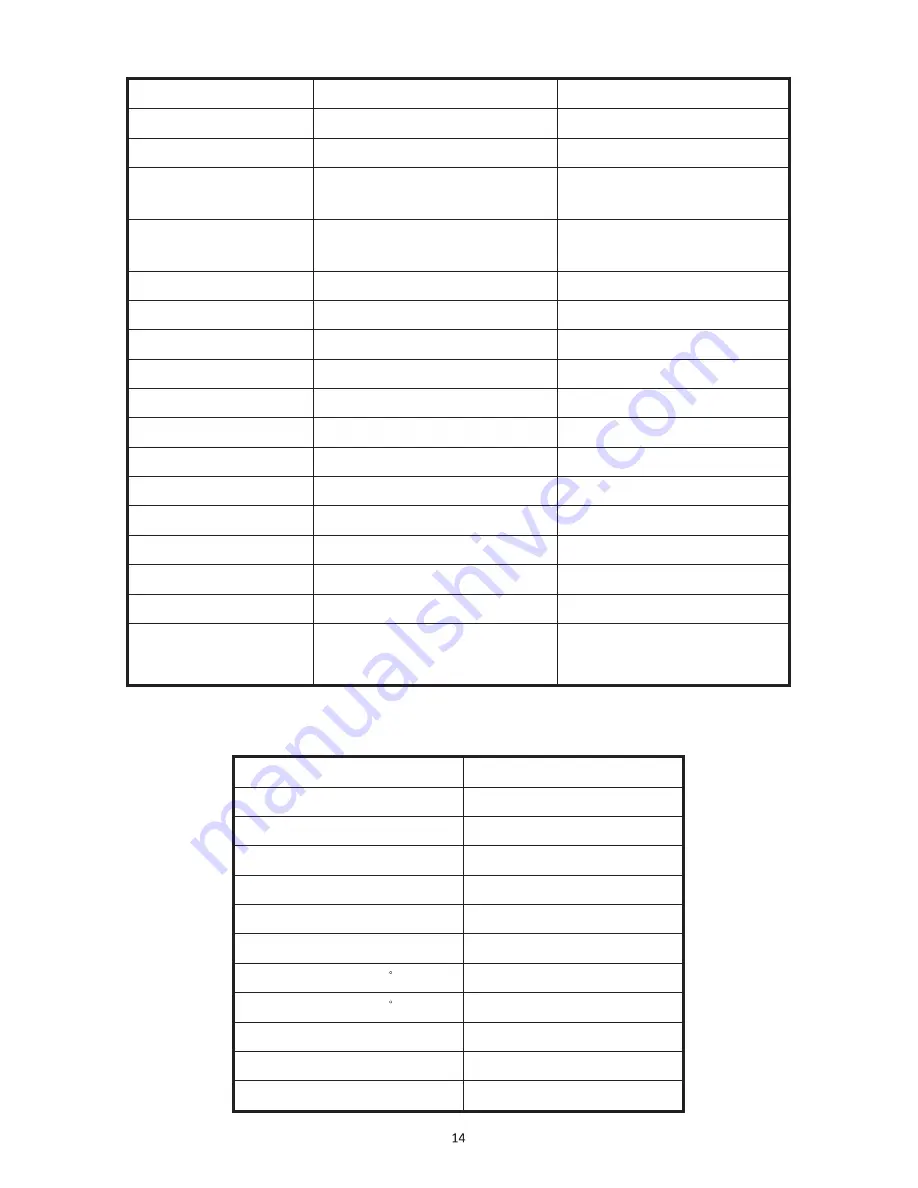

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

•

Metal cutting saw will

•

No supply of power.

•

Check that power is

not start.

•

Brushes worn or sticking

available at source.

•

Switch is faulty.

•

Disconnect power, open

brush

•

Motor components open

caps and ensure brushes

move

or short circuited.

freely in the holders.Check

•

Cord damaged.

whether the brushes require

replacing.

•

Metal cutting saw make

•

Dull or damaged blade or

•

sharpen or replace blade.

unsatisfactory.

incorrect blade for work

being down.

•

Reduce pushing force on Metal

•

Motor is overloaded.

cutting saw.

•

Makes unusual sound.

•

Mechanical obstruction.

•

Contact Repair Center.

•

Armature has shorted sections.

•

Discard blade and change a

•

Blade out of balance.

different blade.

•

Heavy sparking occurs

•

Brush not moving freely.

•

Disconnect power,remove

inside motor housing.

•

Armature short circuited or open brushes,clean or replace.

circuited.commutator dirty.

•

Contact Repair Center

SPECIFICATONS :

Rated voltage

120V~ 50/60Hz

Rated input

1400W

No load speed

3800RPM

Arbor

20.0 mm

Saw blade diameter

185mm(7-1/4")

Arm-held vibration

7.20m/s2 k=1.5

Weight

6.8kg

Max. cutting depth at 90

62mm

Max. cutting depth at 45

40mm

Max. cutting thickness

6mm

Sound power level

98dB(A)

Sound pressure level

88dB(A)

TROUBLESHOTTING :