19

Working with Core Drills

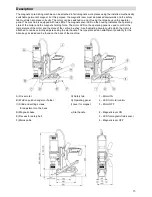

Only use quick-change tool holder on the flat clamping face of the core drill.

Push the centring and ejecting pin through the core drill head.

Align the flat clamping face of the core drill on the marking in the swivel and turn the swivel of the quick-change

tool holder completely clockwise to open the tensioning block.

Insert the core drill and turn the swivel back. Check the correct, firm fit of the core drill.

Risk of injury! Always wear gloves since the edges are sharp.

Set the core drill on the work piece and start drilling until the whole cutting area is marked as a circular ring.

The core drill should be cooled constantly during the drilling process. Optimum cooling is possible through our

coolant equipment using inner cooling.

Do not switch the drive motor off during drilling, and after the drilling process pull the core drill back by turning

the star handle with the motor still running.

Remove swarf and core after every drilling process.

Use swarf hook to remove the swarf. Do not touch with your bare hands. Risk of injury!

Summary of Contents for RB 35 SP

Page 44: ...44 Explosionszeichnung RB 35SP Exploded drawing RB 35SP Vue clat e RB 35SP Despiece RB 35SP...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52 Stand 02 2016...