13

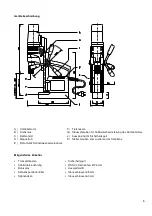

Switching on and off

•

Check connecting line and plug on damages first.

•

Push button MAGNET ON, in order to initiate the magnet and the magnetic adhesion is guaranteed.

•

For non-magnetizable materials, please use the ROTABEST Vacubest (Prod.-No. 18150).

•

When working on walls and ceilings, safe the machine with the safety belt.

For these operations we recommend cooling with our spray ALFRA BIO 2000, Prod.-No. 21010.

•

Push the button MOTOR ON to start the Motor.

•

The magnet foot now reaches its maximum magnetic adhesion! In case of a damaged magnet,

the motor won´t start.

•

To switch off machine proceed in reverse order: MOTOR OFF and then MAGNET OFF.

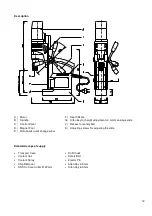

MPI-System

•

At function „magnet on“, 100% of the mangnet power is available right from the beginning.

•

Simultaneously a timing relay will be activated which is preset to 60 seconds. If the motor will not be switched

on after “magnet on” the LED of the magnet switch on the key pad is flashing and a buzzer sounds at the same

time. This time-controlled alarm will be also activated after drilling is done and the motor is switched off but the

magnet is still on.

•

A functional check of the LED and of the buzzer is carried out if the machine will be connected to the mains with

the electric cable (short flashing of the LED and short buzzing). With it it it’s possible to test the model in use

respectively the control in use fast and easily on site.

•

The new PCBs are 100% compatible with machines of older type series, i.e. in case of repair they can be

replaced respectively exchanged without problems.

Summary of Contents for Rotabest 40RQ

Page 27: ...27 Ersatzteile Spare Parts Pi ces de rechange...

Page 31: ...31...