14

•

Do not stop the motor during the drilling process. After the process draw the cutter back with running

motor.

•

Remove chips and core after each drilling.

Remove chips with chip-remover. Do not touch with bare hands. Danger of injury!

How to work with twist drills

•

The drill chuck with Weldon shank (art. no. 18107) is only to be used for drilling with twist drills up to

∅

10 mm.

•

Insert drill chuck with adaptor in the Weldon arbor (E).

•

Insert twist drill in drill chuck and tighten.

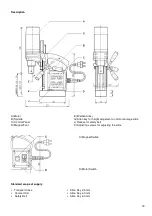

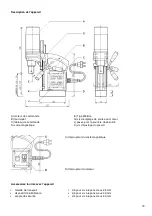

The motor can be continuously adjusted on the slide by releasing the Allan screw

(for a maximum enlargement of the stroke, when using twist drills and drill chucks).

Cleaning and care

Pull plug prior to cleaning to avoid injuries by unintentional switching on.

•

Clean the outside of the motor with dry compressed air.

•

Check connecting lines on damages.

•

Clean and grease sliding surfaces regularly. Should lateral play arise by wear of the dovetail guide this

can be adjusted by adjusting the laterally positioned set screws (K).

•

Carbon brushes should be replaced after appr. 250 hours running time.

•

After the work is finished we recommend to store the Metal Core Drilling Machine in the transport case in

a lying position.