9

Working with core drills

•

Push the ejector pin (centering pin) through the core drill head.

•

Core drills with Weldon shank are tightened with clamping screws (DIN 913) on both clamping surfaces.

Risk of injury! Always wear gloves since the edges are sharp.

•

Set the core drill on the work piece and start drilling until the whole cutting area is marked as a circular ring.

•

The core drill should be cooled constantly during the drilling process. Optimum cooling is possible through our

coolant equipment using internal cooling.

•

Do not switch the drive motor off during drilling, and after the drilling process pull the core drill back with the

motor still running.

•

Remove swarf and core after every drilling process.

Use a swarf key to remove the swarf. Do not touch with your bare hands. Risk of injury!

Special information on handling switchable permanent magnets

The magnetic surface is located on the underside of the core drilling machine and generates the magnetic holding

force when the magnet is activated. The magnet can be activated independently of the 110 volt supply by pressing

the lever down. For the magnet to be released the black safety tab must be pushed in using the ball of your hand

and the lever pulled upwards. The machine remains attached to the work piece even in the event of a power failure

when the lever is still in the down (activated) position

Material thickness

The magnetic flow of the TML permanent magnet requires a minimum material thickness of approx. 3/8” (8 mm) to

be completely absorbed by the work piece. If this material thickness is not sufficient, the maximum holding force is

reduced in accordance with the material thickness. Conventional electric or permanent magnets have a deeply

penetrating magnetic field similar to deep tree roots, and require a large material thickness of more than 1” (25 mm)

to achieve the maximum holding force. The compact magnetic field of the TML magnets is similar to a shallow root

and achieves maximum holding force even with small material thicknesses, so that drilling can be done with

sufficient holding force even on thin sheets from only 1/8-5/32” (3–4 mm) thick.

Material

The load-bearing capacity of the permanent magnets is determined using AISI1020 steel. Steels with a high carbon

content or whose structure has been changed by heat treatment have a low holding force. Foamed or pore-flawed

cast parts also have a lower holding force. This chart shows a comparison of the expected holding force on

different materials.

Material

Magnetic force in %

Non-alloyed steel (0.1-0.3% C content)

100

Non-alloyed steel (0.3-0.5% C content)

90-95

Cast steel

90

Grey cast iron

45

Nickel

11

Stainless steel, aluminium, brass

0

Summary of Contents for ROTABEST RB 50 SP

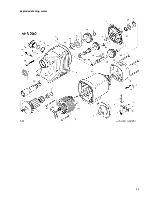

Page 22: ...22 Spare Parts ...

Page 24: ...24 Exploded drawing motor ...

Page 26: ...26 ...

Page 27: ...27 ...