W 3 S E R I E S

H I G H P R E S S U R E A I R C O M P R E S S O R

©ALKIN COMPRESSORS

11

The W3 series compressors are equipped with radiator between the 1st & 2nd stage cylinders and finned tube intercooler

between the 2nd and 3rd stage cylinders and stainless steel aftercooler downstream the 3rd stage cylinder. A moisture trap

(or condensate separator) is installed downstream the 2nd stage intercooler and downstream the aftercooler. Each of these

moisture traps is connected to automatic drain valves that periodically open and drain the condensate in these traps. The

opening intervals and duration is set by a time control relay found in the electrical control panel of the compressor (see the

controls section). This time relay can be adjusted for both functions.

A safety valve is installed between each stage and after the final stage to protect the system against an unexpected pressure

rises due to a malfunctioning valve or component. These safety valves must be inspected periodically to insure proper

operation and set pressure verification (see the

maintenance schedule

for inspection periods).

The W3 series compressors incorporate stainless steel valves on all 3 stages. They are designed to have an unobstructed

passage of air with no pressure loss; they are easy to maintain and replace. Particular attention must be paid to valve

maintenance, as these valves are the basis for proper operation of the compressor package. Do not use oils other than the

recommended oils

in this manual for keeping the valves clean and free of carbon collection. Unsuitable oils will cause

carbonization which will collect on the valve discs and springs, resulting in improper sealing of valves, This will increase

the operating temperatures, generating a chain reaction for further deterioration of the oil and valve operation.

Lubrication is created by dipstick found in the bottom of the 4

th

stage connecting rod. While the crankshaft rotating, the

connecting rod reciprocates and the dipstick enters the oil bath in the bottom of the crankcase; while coming out of this

oil bath, the dipstick splashes oil to the moving parts of the compressor. Efficient oil wiper rings control the economical

lubrication of the system.

See the process and instrument diagram to study the general system layout and operation sequence.

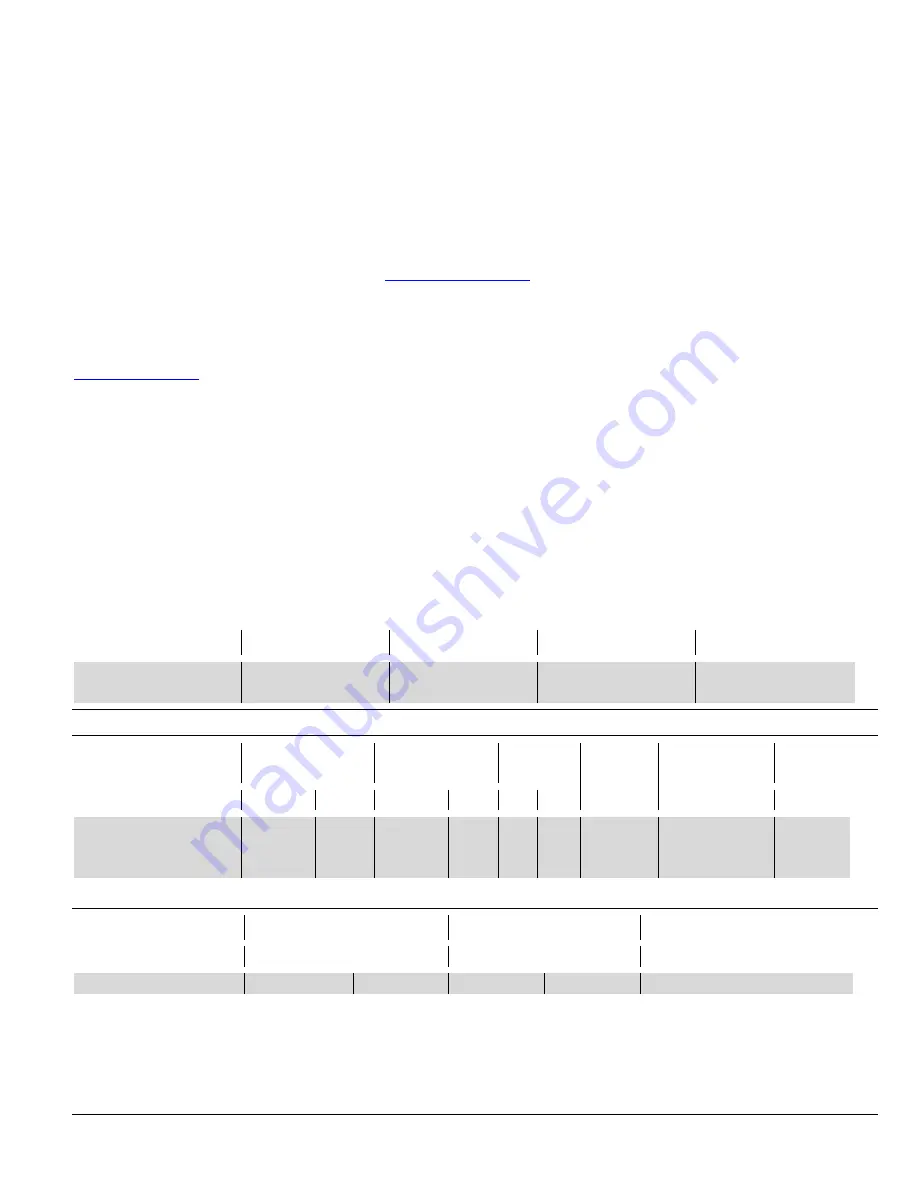

2.2 Thechnical Specifications

Model

Power

Outlet

Working Pressure

Purifier

W3 High Pressure Air

Compressor

30 kw

Single

250 Bar

P61

Performance Data

Model

Max. Working

Pressure

FAD

Power

RPM

Cylinder Bore

Stage

BAR

PSI

Lt/min Cfm HP kW

W3 High Pressure Air

Compressor

250

3625

1350

47

40 30

950

160mmx 2

3/4

”x25mm

3

Stage Pressures

Exit Pressure

1st Stage

2nd Stage

3nd Stage

Bar

Bar

Bar

250 bar

Min.2

Max.5,5

Min. 20

Max. 38

250

Summary of Contents for W3 Series

Page 1: ...W3 SERIES HIGH PRESSURE AIR COMPRESSORS...

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ...W 3 S E R I E S H I G H P R E S S U R E A I R C O M P R E S S O R ALKIN COMPRESSORS 5...

Page 14: ...W 3 S E R I E S H I G H P R E S S U R E A I R C O M P R E S S O R ALKIN COMPRESSORS 9...

Page 26: ...W 3 S E R I E S H I G H P R E S S U R E A I R C O M P R E S S O R ALKIN COMPRESSORS 21...

Page 30: ...W 3 S E R I E S H I G H P R E S S U R E A I R C O M P R E S S O R ALKIN COMPRESSORS 25...