W 3 1 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN Kompresör Sanayi ve Ticaret Limited Şirketi

24

replaced in every general overhaul period. Replacement of the valves can be made by ALKIN Service

Personnel or a trained costumer.

CONSULT THE NEAREST ALKIN DEALER OR ALKIN FOR REPLACEMENT OR

MAINTENANCE.

Breather:

All piston type machines have some compression leak through the rings into the crankcase. There is a

breather system to prevent the pressure built up in the crankcase. In the air compressor the crankcase is

connected to the inlet with a cupper pipe from where the breathing is made possible.

CONSULT THE NEAREST ALKIN DEALER OR ALKIN FOR REPLACEMENT OR

MAINTENANCE.

Pistons:

1

st

, 2

nd

and 3

rd

stg. pistons are connected to the crankshaft via connecting rods. Pistons move up & down and

compress the air inside the cylinders with the motion supplied by crankshaft. Have the pistons tested with

proper testing equipment in general overhaul periods and replace them if exceeding the tolerance limits

mentioned in parts list or having a visible fault.

CONSULT THE NEAREST ALKIN DEALER OR ALKIN FOR REPLACEMENT OR

MAINTENANCE.

Safety Valves:

Safety valves are found at the end of each stage of compressor unit. All the safety valves are subject to

pressure tests and working pressure are set accordingly. Therefore the safety valves prevent the danger in case

of rising pressure in the compressor. Safety Valves are set and sealed by the manufacturer. Do not attempt to

break the seal and change the settings of the safety valves. Otherwise you may cause serious injuries or

accidents may result in death. Check the safety valves in every general overhaul against leakages, by using a

foam water, and replace if necessary. Return the old safety valves back to the manufacturer.

Important

CONSULT THE NEAREST ALKIN DEALER OR ALKIN FOR REPLACEMENT OR

MAINTENANCE.

Intake Filter:

Inlet Filter is used to filter the air particles in the first stage. Replace the inlet filter element in the periods shown in

Maintenance Table.

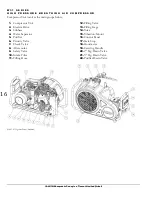

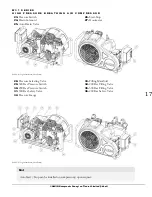

1.6.2 Major Components – System

Subbase:

This is the part carrying the motor and compressor and has been supported with 4 vibration mounts.

Filling System:

The system consists of filling hoses resistant to high pressure on the compressor after the final filter; purifier,

filling valve, yoke, pressure gauge, and DIN Adapter on the hoses which is required to connect and fill the

SCBA cylinders. The number of filling hoses can be increased upon request.