W 3 1 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN Kompresör Sanayi ve Ticaret Limited Şirketi

43

that the piston is well placed.

Reconnect the piping of auto drain valve with appropriate tools

Start the compressor and verify that the drain valve is operating within drain intervals.

2.5.16 Oil Change Instructions

Instruction no

16

Instruction name

Oil Change Instructions

List of tools required

funnel, bowl

No of persons required

1 person

Estimated Completion Time

20 minutes

Parts list to be used in replacement

Anderol 750 oil

Start the compressor and run for 5 minutes to warm up

the oil. Then stop the compressor.

Remove oil top cap with a no.17 wrench.

Put a funnel and a bowl below the oil drain plug.

Remove oil drain cap with a no.17 wrench.

Wait until all oil is drained.

Reinstall oil drain cap with a no.17 wrench.

Refill with new ANDEROL 750 oil.

Reinstall oil top cap with a no.17 wrench.

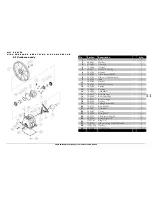

2.5.17 Valve Replace Instructions

2.5.17.1 Initial Operational Check for Valves

After roughly half an hour’s operation, valves should be checked. Note that intake line to valve heads should

be hand warm and outlet-piping should be hot.

Should the intake pipe to the valve head of second stg. heat up excessively, and first stg. safety valve blow off,

this would be an indication that either intake or pressure valve of second stg. is malfunctioning. It is,

therefore, necessary to remove the valve head and check these valves, and/or to replace them.

2.5.17.2 General Instructions for Changing the Valves

Always replace valves as a complete set.

Carefully clean dirty valves. Never use a sharp tool for this purpose. Soak the valves in diesel oil

or petroleum and clean with soft brush.

Check individual components for excessive wear. If the valve seat and valve disks are dented,

replace the valves.

Valve head screws and nuts must be tightened with a torque wrench.

Check the valve space in the valve heads for dirt, and clean if necessary.

Use only appropriate gaskets and O-rings on reassembly.

During reassembly, reassemble step by step.

After finishing all maintenance work on the valves, turn the compressor manually using the

flywheel and check whether all items have been correctly installed.