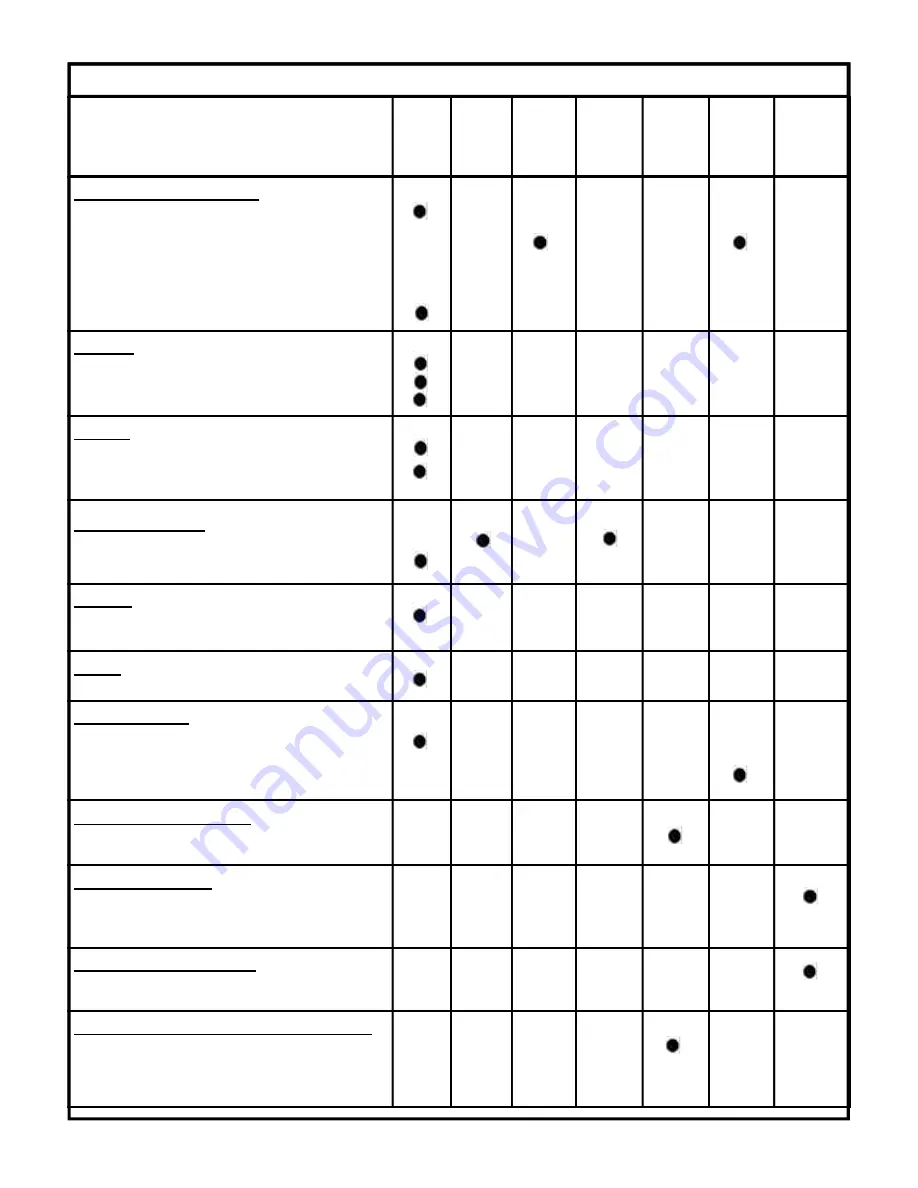

MOTOR DRIVEN OIL FIRED

CLEANERS

DAILY

EACH

HR

FIRST

8 HRS

AFTER

FIRST

50 HRS

EVERY

50 HRS

EVERY

100

HRS

EVERY

500

HRS

YEARLY

OIL BATH WATER PUMP:

Oil Level

–

check and add as needed per PUMP

SERVICE insert.

O i l C h a n g e –

d r a i n a n d r e f i l l p e r P U M P

SERVICE insert

.

CAUTION:

Used oil must be

disposed into an environment safe container and

brought to an oil recycling center.

Oil Contamination –

Milky color indicates water

HOSES:

Blistering, Loose

Covering

Abrasion

of cover exposing reinforcement.

Cuts

exposing reinforcement

BELTS:

Cracks or fraying

Belt Tension -

For correct belt tension, see

MACHINE MAINTENANCE insert.

FILTER – WATER:

Check water inlet

hose screen for debris

Check float tank

screen for debris

LEAKS:

Check

for water and build up of scale at pipe

connections.

FUEL:

Adequate fuel supply.

FILTER—FUEL:

If contaminants

are present see FUEL FILTER

insert.

Remove and Replace

fuel filter per FUEL

FILTER insert.

SCREEN—FUEL PUMP:

Check fuel pump screen

for debris see OIL

BURNER MAINTENANCE insert.

BURNER NOZZLE:

Replace Nozzle

as specified in BURNER

section of MODEL SPECIFICATIONS or BURNER

ASSEMBLY insert.

GUARDS AND SHIELDS:

Check that all guards and shields are in place and

secure.

PUMP MOTOR WITH GREASE FITTINGS:

Remove drain plug. Use 1 or 2 full strokes of shell

"DOBLIUM RB", Chevron "SR1 No.2" or Texaco

"PREMIUM RB". Operate for 20 minutes and

replace drain plug.

MACHINE MAINTENANCE SCHEDULE

13

08-11-04 Z08-03090

Summary of Contents for 3102 Series

Page 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Page 22: ...09 00 Z08 00064 ECN 02311 7 ...

Page 25: ......

Page 26: ......

Page 37: ......

Page 43: ...4 ...

Page 44: ...14 ...

Page 47: ......

Page 48: ......

Page 50: ......