Summary of Contents for 3102 Series

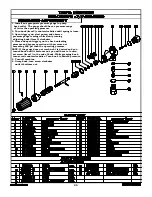

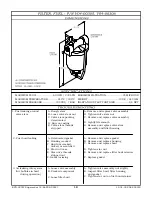

Page 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Page 22: ...09 00 Z08 00064 ECN 02311 7 ...

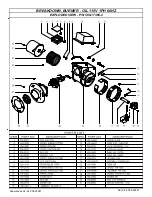

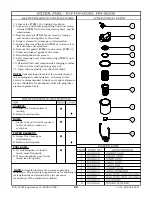

Page 25: ......

Page 26: ......

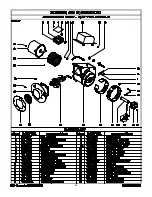

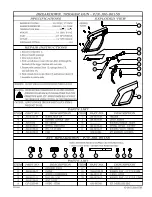

Page 37: ......

Page 43: ...4 ...

Page 44: ...14 ...

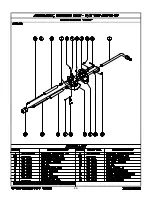

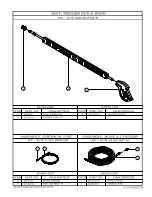

Page 47: ......

Page 48: ......

Page 50: ......