31

Pre-Cleaner Assembly

Valve, Unloader

p/n C07-04504M-A

Fuel Filter V04-00308

Troubleshooting

Trouble

Possible Cause

Remedy

Frequent valve recycles

Damaged check valve O

-

ring Remove and replace

Leaking connections

Check or renew

Restricted bypass or too small

diameter of

the bypass hose

Clean or adapt

passage diameter

Valve does not reach

pressure

Piston O

-

rings worn out

Remove and replace

Debris between seat and

shutter

Clean the seat

Seat worn out

Remove and replace

Nozzle worn out

Remove and replace

Incorrect choice of nozzle

Fit with smaller nozzle

High pressure peaks at

gun closure

There is not a minimum of 5%

of total flow

discharged in bypass

Reset Correctly

Excessive flow in bypass

Change type of valve

or adjust passages

Adjustment with spring totally

compressed

Loosen adjustment

screw and eventually

fit with smaller nozzle

Valve does not

discharge

at low pressure at gun

closure

Jammed check valve

Jammed check valve

Debris on check valve

Clean

Maintenance Procedures

Every 400 working hours, check and lubricate the seals with water resistant

grease with water resistant grease.

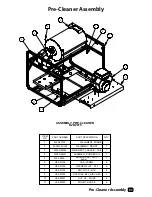

Pre-Cleaner Assembly

1

7

5

2

11

10

8

4

3

9

6

ASSEMBLY, PRE-CLEANER

8

/

28

/20

15

ITEM

NO.

PART NUMBER

PART DESCRIPTION

QTY.

1

5355

-00130

WELDMENT, FRAME

1

2

53052V-10134

WELDMENT, MOUNT

1

3

5305A-00105

WELDMENT, CHASSIS - COIL

1

4

5305A-00401

ASSEMBLY, BURNER-OIL

1

5

F05-00529

ENGINE, GAS - 18HP,

Kohler

1

6

H04-31326

CAP, SCREW

4

7

H05-31300

WASHER, FLAT - 5/16

4

8

H06-31300

NUT, LOCK - 5/16"

8

9

H06-37500

NUT,LOCK-3/8-16UNC HEX

3

10

H06-50001

NUT, 1/2 - 20UNF

8

11

H10-50000

MOUNT, SHOCK

4

Summary of Contents for 5305A

Page 4: ...Month Day Year Operating Hours Maintenance Performed Machine Record...

Page 9: ...5 Trigger Gun Wand 11 Gun Wand Assembly...

Page 14: ...10 Control Panel 31 Coil Outlet Metering Valve Assembly...

Page 17: ...13 Meteing valve Valve Metering...

Page 42: ...38 Burner Burner Exploded View 4 Water Pump...

Page 51: ...47 Tank Assembly...

Page 53: ......

Page 54: ......

Page 55: ......