35

Oil Burner Maintenance

21

Oil Burner Maintenance

PART NUMBER

V00-14283-2

PART NUMBER

V00-14283-5

Oil Burner Maintenance

Oil Fired Cleaners

Air Band Adjustment

Note: The air band adjustment on this burner has been preset at the factor (elevation approximately 1400

feet). On equipment installed where elevation is substantially different, the air band(s) must be readjusted.

1. Loosen the cap screw retaining the air bands.

2. Move the air bands as indicated below with the machine in operation. Note: The air band should

be set so the exhaust gives the smoke spot specified in the GENERAL section of the MACHINE

SPECIFICATIONS on a Shell-Bacharach scale. If a smoke tester is not available, a smoky

exhaust, oily odor, or sweet smell indicates insufficient air while eye-burning fumes indicate too

much air.

3. Tighten the cap screw retaining the air bands.

Fuel Pump Filter

Suntec Pump

1. Shut off fuel supply.

2. Loosen the 4 screws holding the cover to the fuel pump housing.

3. Take cover and cover gasket off and pull strainer off of pump housing.

4.

Clean out any dirt remaining in the bottom of strainer cover. If there is evidence of rust inside of

the unit, be sure to remove water in supply tank and fuel filter.

5. Turn on fuel supply. Failure to do so will result in fuel pump damage.

Fuel Pump Pressure Adjustment

1.

Install a 0-200 PSI Pressure Gauge.

2.

Remove Plug on top of the fuel pump.

3.

Insert a 1/8” Allen Wrench and turn clockwise to increase pressure and counter clockwise to

decrease.

4.

Remove Gauge and reinstall plug.

Fuel Filter, Adjustment Air Band , Fuel Pressure

Burner Maintenance

Summary of Contents for 5305A

Page 4: ...Month Day Year Operating Hours Maintenance Performed Machine Record...

Page 9: ...5 Trigger Gun Wand 11 Gun Wand Assembly...

Page 14: ...10 Control Panel 31 Coil Outlet Metering Valve Assembly...

Page 17: ...13 Meteing valve Valve Metering...

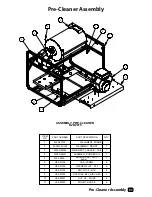

Page 42: ...38 Burner Burner Exploded View 4 Water Pump...

Page 51: ...47 Tank Assembly...

Page 53: ......

Page 54: ......

Page 55: ......