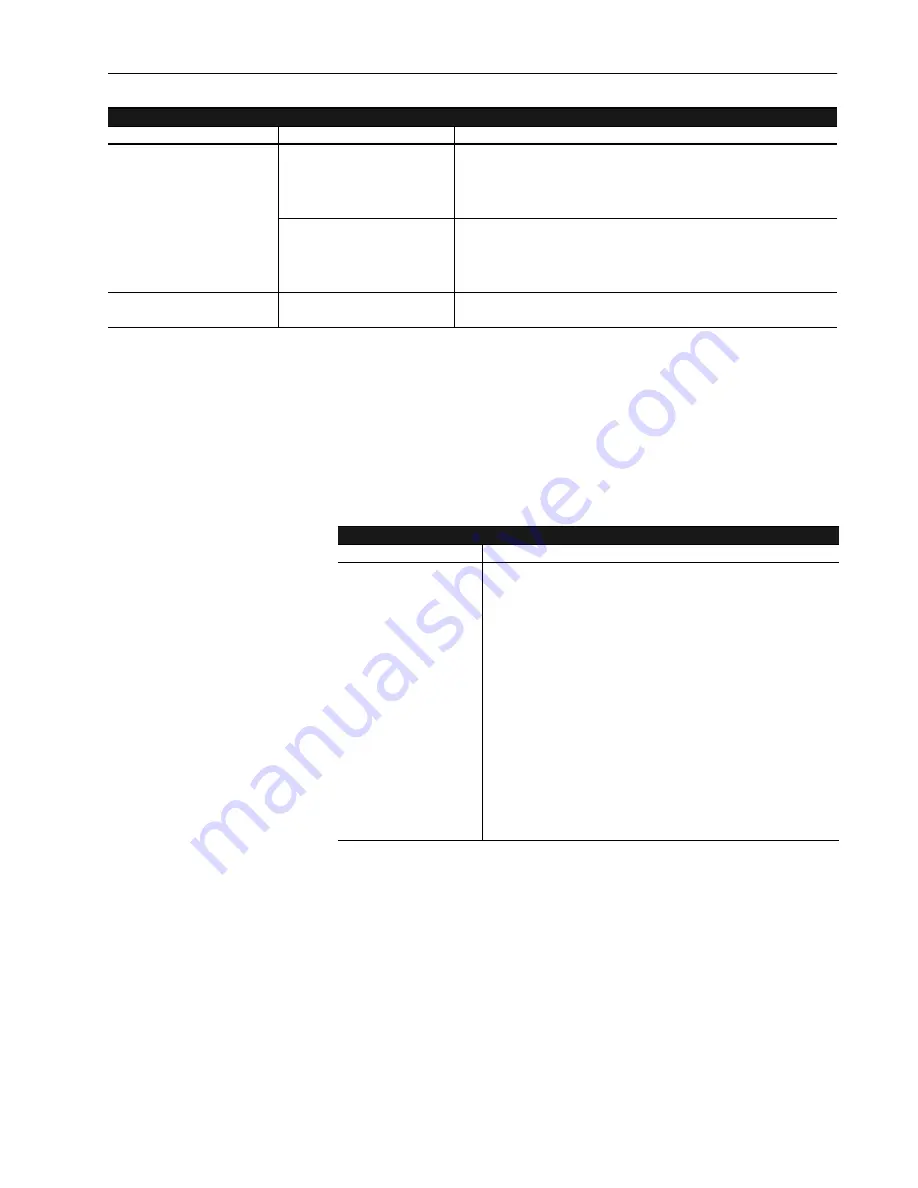

Malfunctions Not Indicated by a Fault

3-3

Link/Configuration

Parameter Malfunctions

The configuration parameters determine where and how the real–time Input

and Output signals will be used by the 1395 drive. These types of problems

can usually be avoided if the Start–up Procedure is closely followed and the

application is well defined. Often the problem can be tracked to a parameter

entry error during programming.

Velocity Control

Malfunctions

Velocity control is the function block which controls the direction and

velocity of the motor. This function block has many set–up and

configuration parameters which can affect the operation and performance of

the drive. It deals not only with velocity regulation but with torque

regulation and most motor related functions. It is important that the Start–up

procedure has been properly performed before attempting these

troubleshooting techniques.

The following table lists malfunctions, symptoms and possible solutions.

Drive Stops even though No

STOP Command was Issued.

STOP (bit 11) is set in one of the

logic commands.

•

A safety system external to the drive is issuing a STOP command. This

could be coming through any of the Adapters.

•

The STOP key on the Bulletin 1300 Programming Terminal was

pressed which will stop the drive regardless if LOCAL mode is active.

No STOP bits were set, drive

stopped.

•

ECOAST string was opened during operation. ECOAST string must be

closed prior to attempting to restart the drive.

•

A drive fault was detected and stopped the drive. Examine the Fault

Queue to determine the exact cause.

Contactor Remains Closed

After A STOP Command.

No STOP bits were set, drive

stopped.

•

The Close Contactor (bit 13) is set in the logic command. Determine

what is activating this bit and correct.

Logic Control Malfunctions

Malfunction

Symptom

Solution

Link/Configuration Parameter Malfunctions

Malfunction

Solution

An error in the

configuration of the drive

often exhibits itself in sink

parameters not reflecting

the desired input signals

from the source

parameters.

•

The easiest way to troubleshoot this type of problem is to start

examining the source parameter closest to the actual input. In the

case of a signal coming from one of the adapters, verify that the

source parameter data is correct. If it is not, the problem exists

between the origin of the signal and the Adapter Board.

•

If the adapter’s source parameter is correct then check the sink

parameter that is linked to it. The data should be exactly the

same, taking into account any unit conversions that may exist. If

the data is not exact, a problem in the configuration links exist.

This methodology can be used to track data throughout the 1395

drive.

•

If the 1395 has experienced a Hard or Soft Fault, the System

Processor will not process configuration links that direct data

transfer to, or from, a processor that is faulted. The same is true if

an attempt to direct data to an adapter board that is not mounted

is attempted.

Aotewell Ltd industry-mall.net

www.aotewell.com

sales@aotewell.com

www.aotewell.com