Compact 32-point 24V dc Sink/Source Input Module

5

Publication 1769-IN032A-EN-P - April 2003

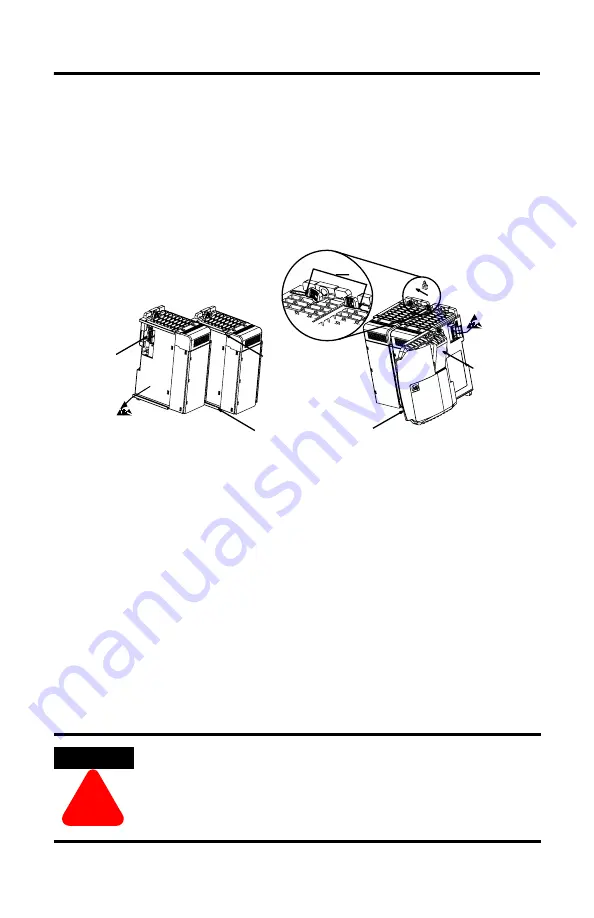

System Assembly

The module can be attached to the controller or an adjacent I/O module

before

or

after

mounting. For mounting instructions, see Panel Mounting on page 6, or DIN

Rail Mounting on page 8. To work with a system that is already mounted, see

Replacing a Single Module within a System on page 8.

The following procedure shows you how to assemble the Compact I/O system.

1.

Disconnect power.

2.

Check that the bus lever of the module to be installed is in the unlocked

(fully right) position.

3.

Use the upper and lower tongue-and-groove slots (1) to secure the modules

together (or to a controller).

4.

Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

5.

Push the bus lever back slightly to clear the positioning tab (3). Use your

fingers or a small screw driver.

6.

To allow communication between the controller and module, move the bus

lever fully to the left (4) until it clicks. Ensure it is locked firmly in place.

ATTENTION

!

When attaching I/O modules, it is very important that the bus

connectors are securely locked together to ensure proper

electrical connection.

1

1

2

6

5

4

3

30536-M