Installation Instructions

Block I/O

Cat. No. 1791-0A32 Series B

2

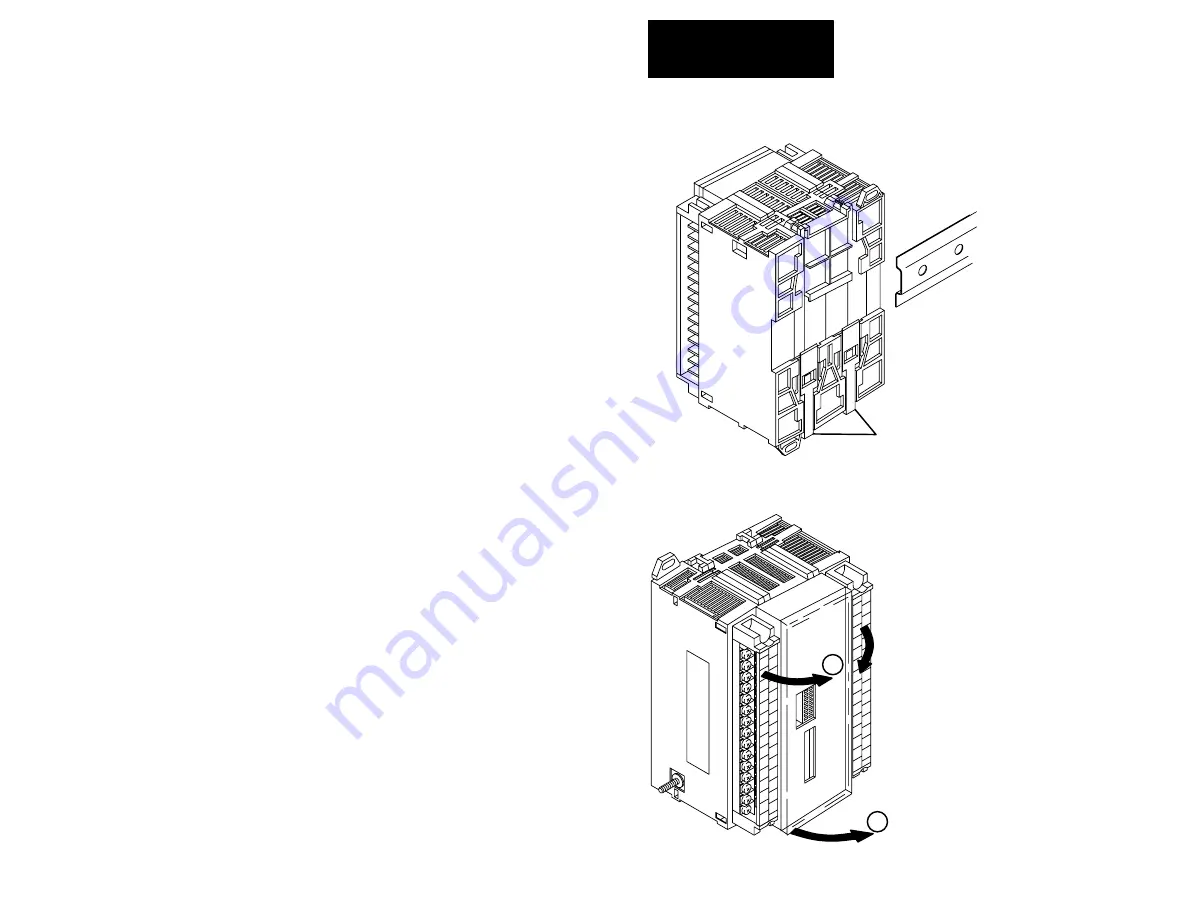

Figure 2

Mounting on a DIN Rail

1. Hook top of slot over DIN rail.

2. While pressing block against rail, pull

down on locking levers.

3. When block is flush against rail, push up

on locking levers to secure block to rail.

Locking levers

DIN Rail

A-B Pt. No. 199-DR1

46277-3

EN 50022

(35 x 7.5mm)

Figure 3

Inserting Labels

A set of die-cut labels is supplied with your

module. Select the proper module

designation labels (PLC or SLC) for the front

door and terminal strips.

1. Remove labels from package. Select

correct labels for your application. (PLC

label is numbered 00–07 and 10–17. SLC

is numbered 00–07 and 08–15.)

3. Open clear front door. Insert module

designation label into slots in door.

2. Remove plastic cover on terminal strip

by flexing in middle. Slip the terminal

designation label with power and RIO

designations into built-in holders in left

terminal strip cover. Flex cover slightly

to install. Repeat for the other

terminal strip using the remaining label.

2

3