84

Rockwell Automation Publication 825-UM004D-EN-P - November 2012

Chapter 6

Configuring Protection & Logic Functions

When the 825-PR12D Module is not connected to the relay, disable the RTD

function by setting RTD ENABLE equal to N.

Setting RTD RESET MODE determines the reset mode for the RTD element.

If set to Auto mode, the RTD trip resets automatically when the element resets,

provided no other trip conditions are present. If set to Man, operator

intervention (e.g., front-panel push button) is required to reset the RTD trip.

The relay allows you to independently define the location of each monitored

RTD using the RTD LOCATION settings.

Define the RTD Location settings using the following suggestions:

•

If an RTD is not connected to an input, or has failed in place and is not

being replaced, set the RTD Location for that input to Off.

•

For RTDs embedded in motor stator windings, set the RTD Location

equal to WDG.

•

For inputs connected to RTDs measuring bearing rise temperature, set the

RTD Location equal to BRG.

•

For the input connected to an RTD measuring ambient motor cooling air

temperature, set the RTD Location equal to AMB. Only one ambient

temperature RTD is allowed.

•

For inputs connected to monitor temperatures of another apparatus, set

the RTD Location equal to OTH.

The relay allows you to independently define the type of each monitored RTD

using the RTD Type settings.

NOTE:

A fiber optic cable is not included with the 825-PR12D. A simplex 62.5/125 μm fiber-optic

cable with ST connector is needed for connecting the 825-PR12D to the 825-P (eg., part#

1570FCBL-MM-SX-62-STST-2M from Ultra Spec Cable - http://store.ultraspec.us).

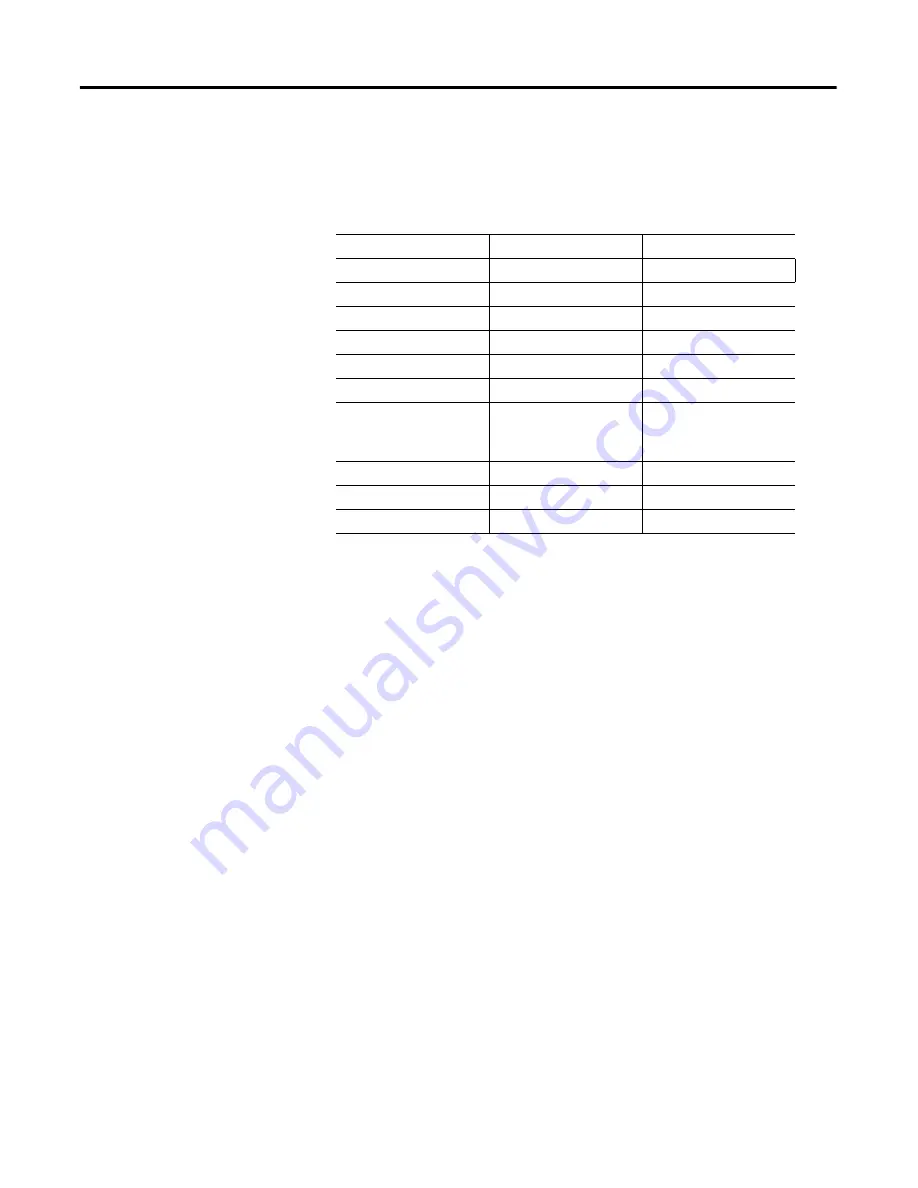

Table 27 - RTD Settings

Setting Prompt

Setting Range

Factory Default

RTD ENABLE

Y, N

N

RTD RESET MODE

Man, Auto

Man

RTD1 LOCATION

Off, WDG, BRG, AMB, OTH

Off

RTD1 TYPE

PT100, NI100, NI120, CU10

PT100

RTD1 TRIP LEVEL

Off, 1…250°C

Off

RTD1 WARN LEVEL

Off, 1…250°C

Off

•

•

•

•

•

•

•

•

•

WIND TRIP VOTING

Y, N

N

BEAR TRIP VOTING

Y, N

N

TMP RTD BIASING?

Y, N

N

Summary of Contents for 825-P

Page 1: ...Modular Protection System for Motors Catalog Number 825 P User Manual...

Page 4: ...4 Rockwell Automation Publication 825 UM004D EN P November...

Page 64: ...64 Rockwell Automation Publication825 UM004D EN P November 2012 Chapter 5 Using MPS Explorer...

Page 234: ...234 Rockwell Automation Publication 825 UM004D EN P April 2012 Chapter B ParameterList...

Page 265: ......