18

Rockwell Automation Publication SAFETY-AT140A-EN-P - May 2015

Safety Function: Actuator Subsystems – Stop Category 1 via the PowerFlex 525 and PowerFlex 527 Drives with Safe Torque-off

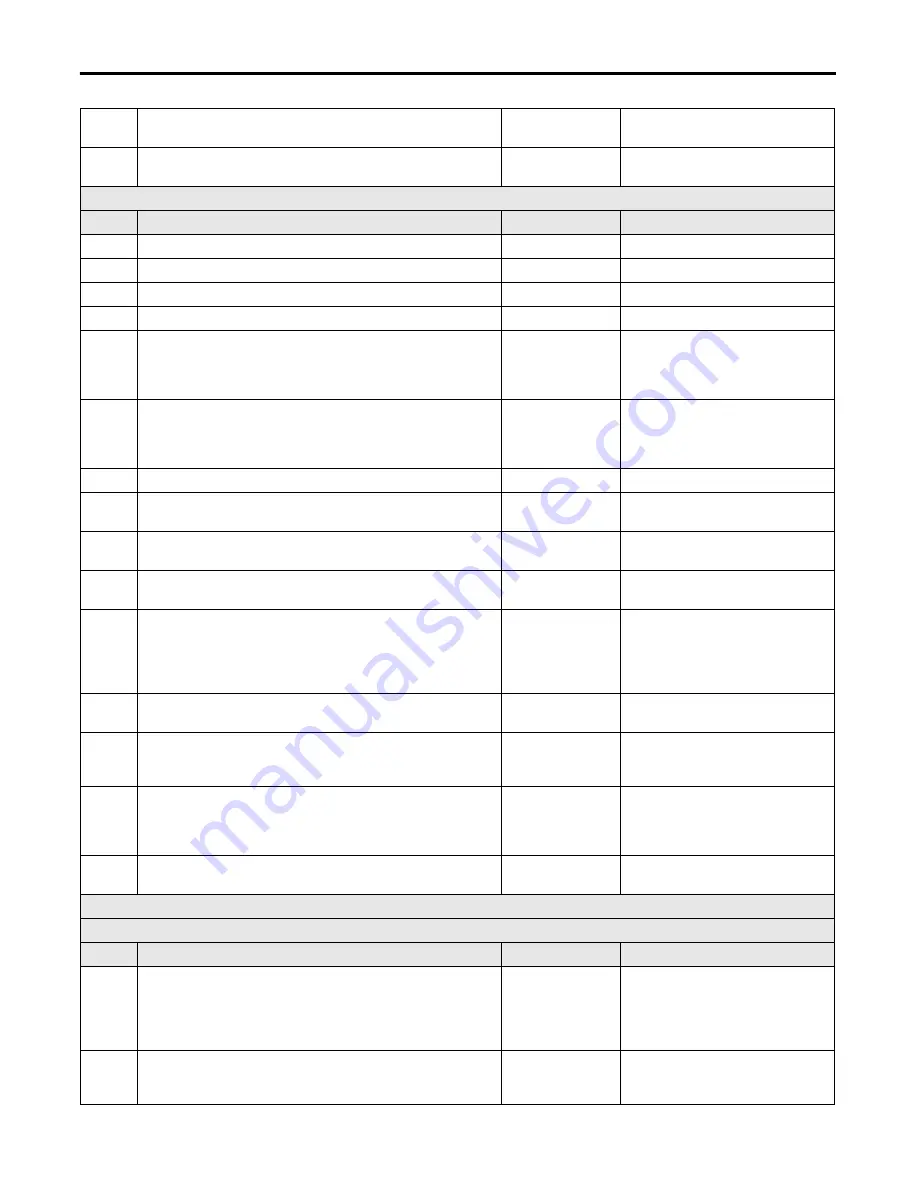

3

Confirm that the Guardmaster dual-input safety relay is set to the proper Logic

configuration setting "2."

4

Confirm that the Guardmaster multifunction-delay expansion module is set to the

proper Range configuration setting "1" and Time configuration setting "1."

Normal Operation Verification - The safety system responds properly to all normal Start, Stop, Reset, and Sensaguard Switch inputs.

Test Step

Verification

Pass/Fail

Changes/Modifications

1

Confirm that no one is in the guarded area.

2

Confirm that the hazardous motion is stopped.

3

Confirm that the door is closed.

4

Apply power to the safety system.

5

Confirm that the PWR/Fault, IN1 and IN2 status indicators of the Guardmaster dual-

input safety relay are green. Confirm that the OUT status indicator blinks green.

Confirm that the PWR/Fault status indicator of the Guardmsater multifunction-delay

expansion module is steady green.

6

Press and release the Reset button. Confirm that the Guardmaster dual-input safety

relay OUT status indicator is now steady green. Confirm that the Logic IN and OUT

status indicators of the Guardmaster multifunction-delay expansion module are

steady green.

7

Confirm that the hazardous motion does not start on powerup.

8

Press and release the external drive Start button. Confirm that the hazardous motion

begins and the machine begins to operate.

9

Press the external Stop button. The machine must stop in its normal, configured

manner. The safety system must not respond.

10

Press and release the external Start button. Confirm that the hazardous motion starts

and the machine begins to operate.

11

Open the guarded door. The safety system must trip. The hazardous motion must stop

within the required time. Monitor the status indicators on the Guardmaster dual-input

safety relay and Guardmaster multifunction-delay expansion module for proper

operation. Only the PWR/Fault status indicator on both devices should be steady

green. All other status indicators should be OFF.

12

Press and release the Reset button. The Guardmaster dual-input safety relay and the

Guardmaster multifunction-delay expansion module must not respond.

13

Close the guarded door. The machine must not start. The IN1 and IN2 status indicators

of the Guardmaster dual-input safety relay must be steady green. The OUT status

indicator must blink green.

14

Press and release the Reset button. Confirm that the Guardmaster dual-input safety

relay OUT status indicator is now steady green. Confirm that the Logic IN and OUT

status indicators of the Guardmaster multifunction-delay expansion module are

steady green.

15

Press and release the external Start button. Confirm that the motor starts and the

machine begins to operate.

Validation of Safe Response to Abnormal Operation - The safety system responds properly to all foreseeable faults with corresponding diagnostics.

SensaGuard Switch - Guardmaster input Tests

Test Step

Validation

Pass/Fail

Changes/Modifications

1

Keep the guarded door closed. Hazardous motion continues to run. Remove the gray

wire from the SensaGuard switch to terminal S12 of the Guardmaster dual-input

safety relay. The Guardmaster dual-input safety relay and the Guardmaster

multifunction-delay expansion module must trip immediately. The hazardous motion

must stop. Verify proper operation of all status indicators.

2

Reconnect the wire to the S12 terminal. The Guardmaster dual-input safety relay must

not respond. Press and release the Reset button. The Guardmaster dual-input safety

relay must not respond.