2

Rockwell Automation Publication 440T-IN016C-EN-P - January 2018

Prosafe Electronic Time Delay Unit

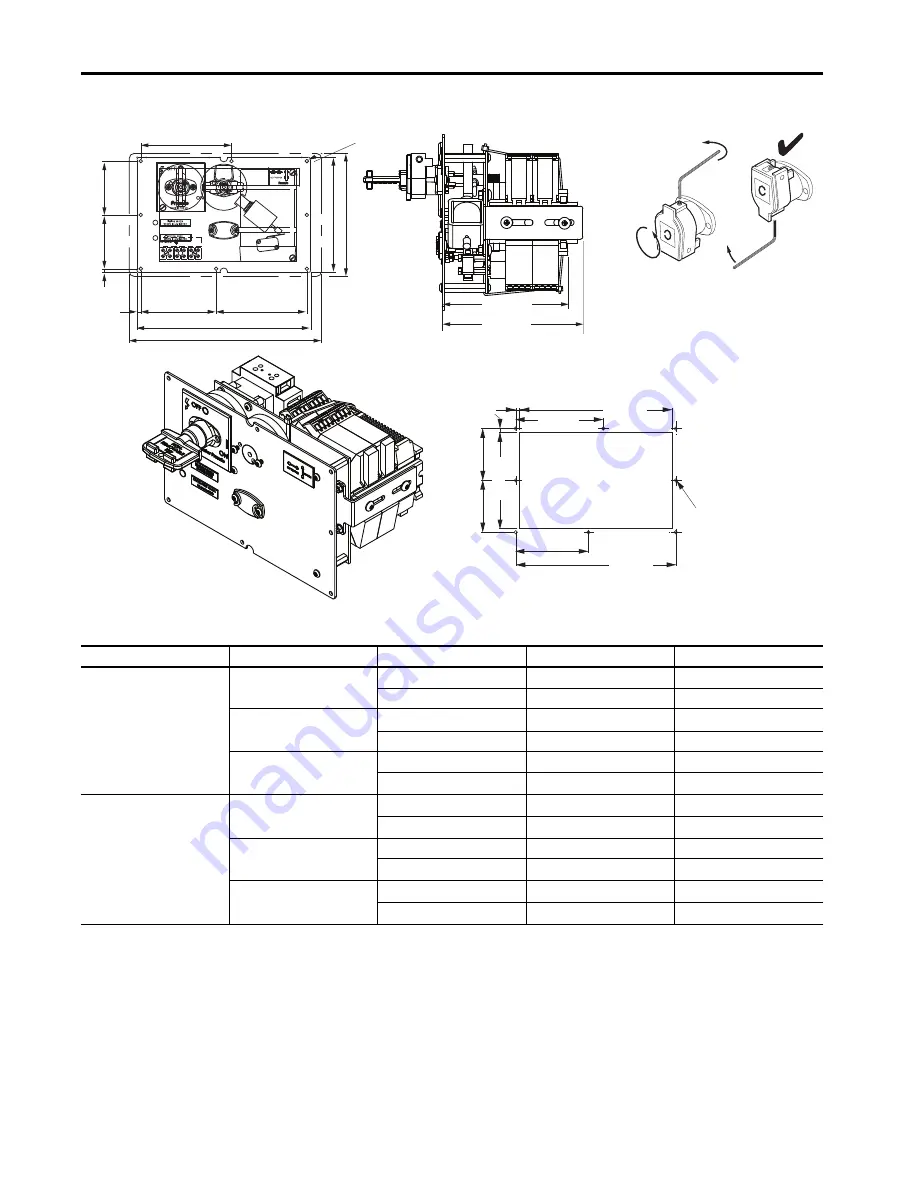

Figure 2 - Dimensions [mm (in.)]

Table 2 - Product Specifications

Type

Input Voltage

Contact Set 1

Contact Set 2

Catalog Number

Single Key Out Panel Mounted

24V DC

3 N.O. 40 A

1 N.O. 20 A

440T-MSTUE10

2 N.O. 20 A

1 N.C. 20 A

440T-MSTUE11

110V AC

3 N.O. 40 A

1 N.O. 20 A

440T-MSTUE20

2 N.O. 20 A

1 N.C. 20 A

440T-MSTUE22

230V AC

3 N.O. 40 A

1 N.O. 20 A

440T-MSTUE30

2 N.O. 20 A

1 N.C. 20 A

440T-MSTUE33

Dual Key Out Panel Mounted

24V DC

3 N.O. 40 A

1 N.O. 20 A

440T-MDTUE10

2 N.O. 20 A

1 N.C. 20 A

440T-MDTUE11

110V AC

3 N.O. 40 A

1 N.O. 20 A

440T-MDTUE20

2 N.O. 20 A

1 N.C. 20 A

440T-MDTUE22

230V AC

3 N.O. 40 A

1 N.O. 20 A

440T-MDTUE30

2 N.O. 20 A

1 N.C. 20 A

440T-MDTUE33

5

(0.2)

70

(2.75)

70

(2.75)

130

(5.12)

206 (8.11)

118 (4.64)

8 (0.31) x 4.5 (0.18)

Ø

98 (3.85)

216 (8.50)

2.5 mm

1

2

3

Installed units with flip cap hinge uppermost.

8 (0.31) x 4.5 (0.18)

Ø

160 (6.3)

150 (5.9)

70.0 (2.75)

70.0 (2.75)

5.0

(0.19)

118.0 (4.65)

118.0 (4.65)

98.0 (3.86)

5.0 (0.19)

226 (8.90)

250 (9.84)

115.85 (4.56)

123.85 (4.88)