2

Rockwell Automation Publication 2090-IN012E-EN-P - February 2019

Shaft Seal Kits

About Shaft Seals

A shaft seal is recommended if the motor shaft and end bell are exposed to significant amounts of

containments, such as oil, fluids, or fine dust. Use a shaft seal in these environments to prolong

the life of the motor. A shaft seal and Bulletin 2090 cables with environmentally sealed

connectors are required for an IP66 rating or greater.

See Kinetix Motion Accessories Specifications Technical Data, publication

find Bulletin 2090 cables with environmentally sealed connectors for your motor.

Required Tools

Use these tools to install a shaft seal:

• Appropriately sized screw or bolt to grip and remove the worn shaft seal

• Rubber/wooden mallet or a metal hammer and wooden work piece

• Socket, pipe, or tubing (various sizes)

• Abrasive cloth to remove any nicks or burrs from the motor shaft

IMPORTANT

The shaft seal is not required in applications where the motor shaft and end bell are free of oil,

fluids, or fine dust, and a lower IP rating is sufficient.

Shaft seals are subject to wear and require periodic inspection and replacement. Replacement

is recommended every 3 months, not to exceed 12 months, depending on use.

If you paint the motor, do not get paint on the shaft seal area or the shaft, as this can decrease

the life of the shaft seal.

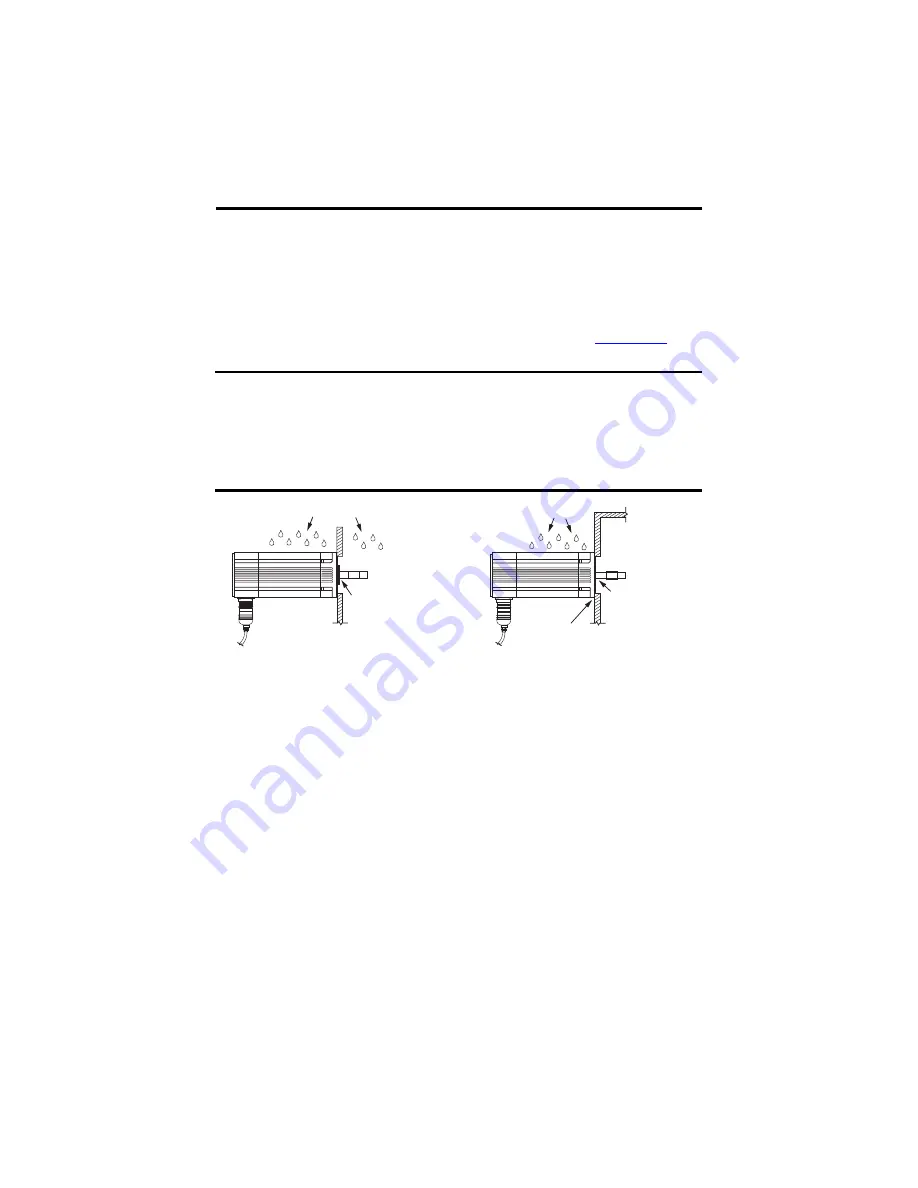

Oil, Fluids, and Fine Dust

Oil, Fluids, and Fine Dust

Shaft Seal Installation

is Recommended

Shaft Seal Installation

is Not Recommended

Motor Shaft and

End Bell are Exposed

to Containments

Motor Shaft and

End Bell are Protected

From Containments

Oil, Fluids, and Fine Dust

Shaft Seal Installation

is Not Recommended