1A

OPERATIONS

1.7 Description

The Riding Trowel is a modern high production machine. Finishing rate will vary depending on the operators

skill and job conditions. The Riding Trowel has eight finishing blades. The Super Duty Gearboxes are designed

to provide exceptional performance with low maintenance and trouble free use under some of the most worse

conditions. All Allen Engineering

Razorback

®

Riders

are equipped with a safety shutdown switch and a low oil

shut down for added job safety and engine protection. Operating time between fuel refills is approximately 2-

1/2 to 3 hours with a rotor speeds of 110 to 145 RPM for PRO 1200 SD series. The

Razorback

®

Riders

are

the most technically advanced trowels on the market today. With Proper maintenance and use your Riding

Trowel will provide you with exceptional service.

1.8 Before Starting

Before starting trowel check the following:

*

Oil level in engine

*

Oil level in trowel gearboxes

*

Fuel level

*

Condition of air filter

*

Condition of trowel arms and blades

*

Grease trowel daily

1.9 Starting

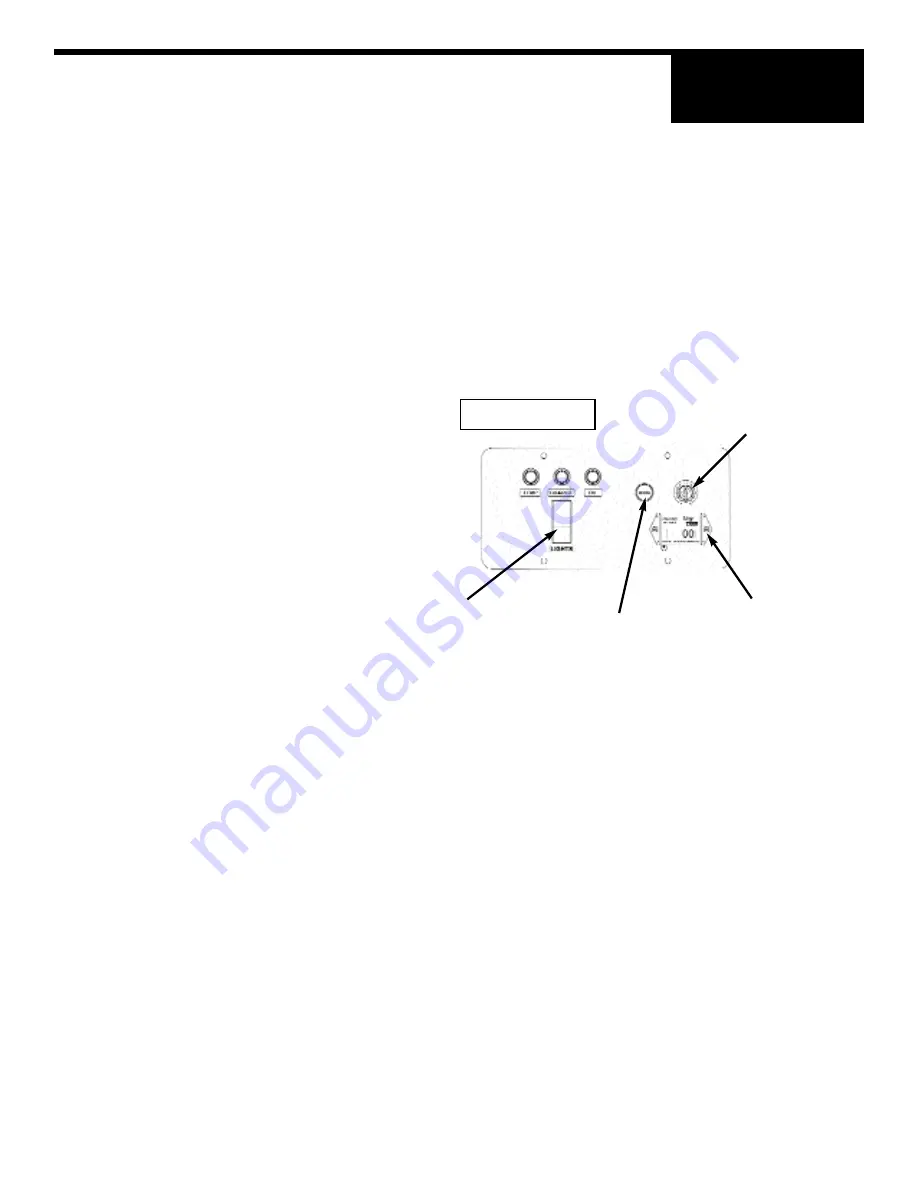

Before starting trowel refer to drawing above for location and identification of controls.

1. Sit down correctly on the Riding Trowel Seat. DO NOT attempt to start the Riding Trowel with out

an operator in the seat.

2. Place left foot on the safety switch pedal located on the operators left hand side. Press down

gently engaging the safety switch and maintain slight pressure.

3. If engine is cold pull out the choke lever located on the control panel (refer to drawings

above).

4. Press down on throttle pedal (located by the operator's right foot) one to two times. NOTE:

To much throttle during start-up will flood the engine.

5. Turn key to the start-position. immediately release key when engine starts. If after two or

three attempts the engine has not started push in choke. This will open the choke. Attempt to

start trowel again. Allow engine to warm up before operating trowel.

Caution:

Operating the starter for more than 5 seconds can damage the starter or engine. If engine fails to

start release the switch and wait 10 seconds before operating starter again.

KEY SWITCH

HOURMETER

CHOKE KNOB

LIGHT SWITCH

1A-10

VANGUARD CONTROL

PANEL SHOWN

Summary of Contents for 032034

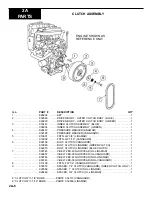

Page 23: ...2A PARTS ENGINE MOUNT SYSTEM 2A 4 VANGUARD LINAMAR...

Page 27: ...2A PARTS SUPER DUTY SD GEARBOX RIGHT HAND SITTING ON MACHINE SOM PART 029141 2A 8...

Page 29: ...2A PARTS 2A 10 SUPER DUTY SD GEARBOX LEFT HAND SITTING ON MACHINE SOM PART 029142...

Page 31: ...2A PARTS FUEL SYSTEM ASSEMBLY 2A 12...

Page 33: ...2A PARTS 2A 14 ELECTRICAL COMPONENTS...

Page 35: ...2A PARTS 2A 16 VANGUARD WIRING DIAGRAM...

Page 37: ...2A PARTS 2A 18 PITCH CONTROL ASSEMBLY...

Page 39: ...2A PARTS STEERING LEVER ASSEMBLY 2A 20...

Page 41: ...2A PARTS SPRAY SYSTEM ASSEMBLY 2A 22...

Page 43: ...2A 24 2A PARTS SPIDER ASSEMBLY...