1A

OPERATIONS

1.14 Periodic Maintenance Schedule

The chart below list basic trowel and engine maintenance. Refer to engine manufacturer's Operation Manual

for additional information on engine maintenance. A copy of the engine Operator's Manual was supplied with

the machine when it was shipped. To Service the engine pull the seat locking pin out and tilt seat back.

DAILY EVERY 20 EVERY 50

EVERY 100 EVERY 300

HOURS HOURS HOURS HOURS

GREASE TROWEL ARMS

X

CHECK OIL LEVEL IN G-BOX

X

CHECK FUEL LEVEL

X

INSPECT AIR FILTERS

X

REPLACE AS NEEDED

CHECK AND TIGHTEN

X

EXTERNAL HARDWARE

GREASE CONTROL LINKAGE

X

CHECK DRIVE BELTS

X

CHECK VALVE CLEARANCE

X

CHANGE ENGINE OIL

X

REPLACE OIL FILTERS

X

OIL CROSSHEAD

X

GREASE TROWEL G-BOX

X

REPLACE SPARK PLUG

X

1.15 Trowel Gearbox

1. Check Oil levels in the gearbox daily (every 8 hours) Add oil if oil level is below the check sight glass. To add

oil tilt trowel back and remove the side plug. Add Oil through hole opening. Replace plug after proper level has

been achieved. DO NOT Fill past the plug. Use only Mobil Oil SHC 634, synthetic ISO VG 460.

2. Each Gearbox has a grease fitting on top cover that must be greased (2 SHOTS ONLY) every 300 operat-

ing hours. Use only Mobilith SHC 220. Extended pressure grease.

1A-13

Summary of Contents for 032034

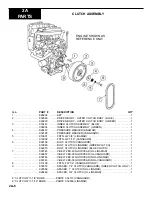

Page 23: ...2A PARTS ENGINE MOUNT SYSTEM 2A 4 VANGUARD LINAMAR...

Page 27: ...2A PARTS SUPER DUTY SD GEARBOX RIGHT HAND SITTING ON MACHINE SOM PART 029141 2A 8...

Page 29: ...2A PARTS 2A 10 SUPER DUTY SD GEARBOX LEFT HAND SITTING ON MACHINE SOM PART 029142...

Page 31: ...2A PARTS FUEL SYSTEM ASSEMBLY 2A 12...

Page 33: ...2A PARTS 2A 14 ELECTRICAL COMPONENTS...

Page 35: ...2A PARTS 2A 16 VANGUARD WIRING DIAGRAM...

Page 37: ...2A PARTS 2A 18 PITCH CONTROL ASSEMBLY...

Page 39: ...2A PARTS STEERING LEVER ASSEMBLY 2A 20...

Page 41: ...2A PARTS SPRAY SYSTEM ASSEMBLY 2A 22...

Page 43: ...2A 24 2A PARTS SPIDER ASSEMBLY...