07/2014

Page 17

SECTION 3

SERVICE

Service (cont’d)

Fuel, Lubricant

Transportation and Storage

Lifting

Where it is necessary to use lifting equipment to position the rammer, check and con

fi

rm that the rubber

isolators on the operation handle is not damaged or cracked. If they are cracked or damaged, replace

the rubber isolators before attempting to lift the machine. Also make sure that the lifting equipment has

a WLL (Working Load Limit) suitable for the rammer’s weight (See speci

fi

cation chart on page 19 or the

machine number plate). Attach suitable chains or slings ONLY to the lifting point on top of the rammer’s

operating handle.

•

NEVER leave the engine running whilst transporting or moving the rammer, even if it is only a

short

distance.

•

The height of the operating handle can be adjusted within the range of 850 ~ 880 mm. Loosen

three bolts at each side of the operating handles base, and retighten them at the desired

handle height. Note that when the handle is set too high, excessive vibration may be transmit-

ted through the handle.

On Site Transport

The rammer may be moved vertically by 2 people, or laid only on the Transport Rollers.

Road Transport

The rammer must be transported as far as possible standing up, strapped to the body side board of

the truck, or strapped inside a lorry (panel truck). If not possible, it may be laid down (engine facing up-

wards, not on its sides) only on the Transport Rollers, in a stable position and strongly strapped down

to guard against rolling or sliding.

Wait until the unit is completely cool before laying it down.

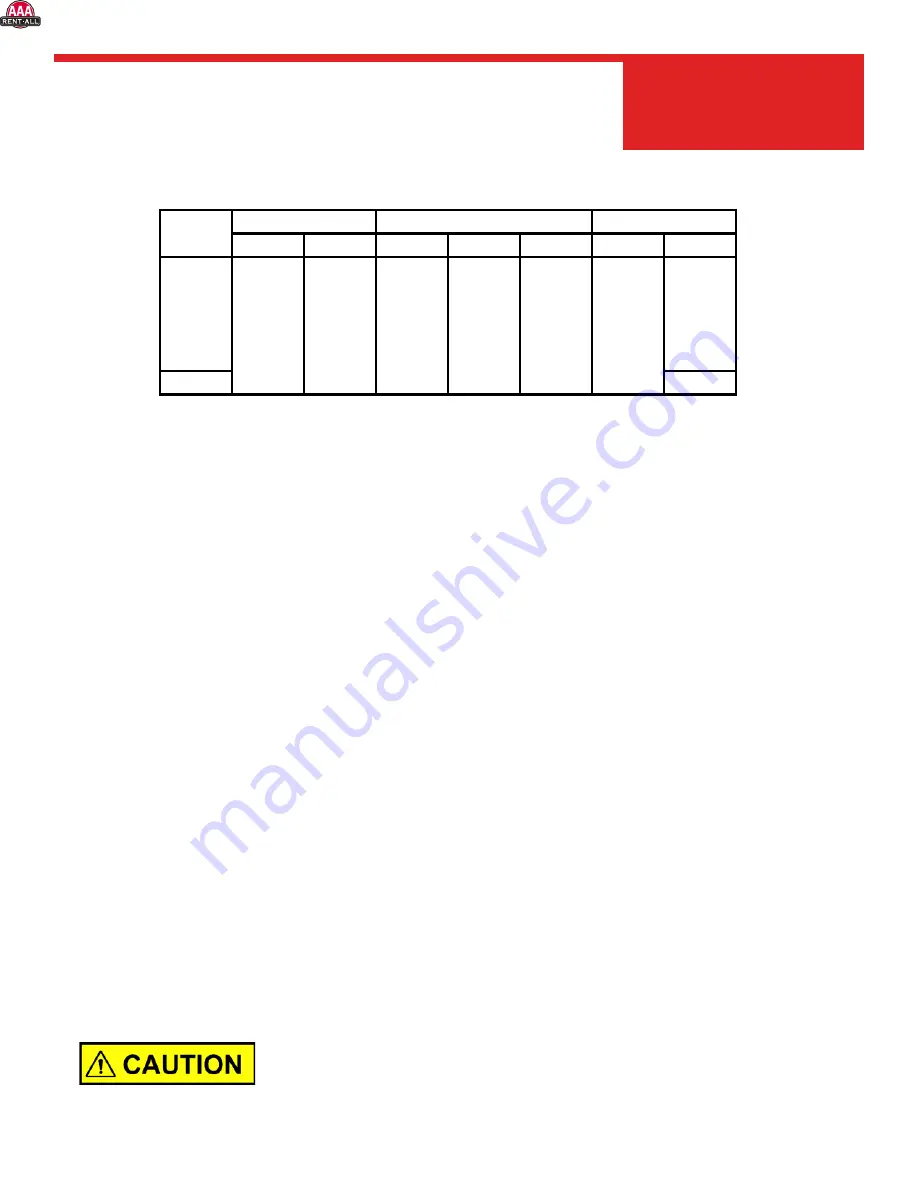

Model

Fuel

Engine Crankcase

Ramming Cylinder

Type

Capacity

Type

Engine

Capacity

Type

Capacity

ATC130H Unleaded

Gasoline

3.8L

SAE

GX100

0.30L

SAE

0.5L

10W – 30,

10W – 30,

API,

API,

SG,

SG,

SF/CC,

SF/CC,

ATC170H

CD

CD

0.8L

*Always follow manufacturer instructions*

*AAA Rent-All 225-291-1356*