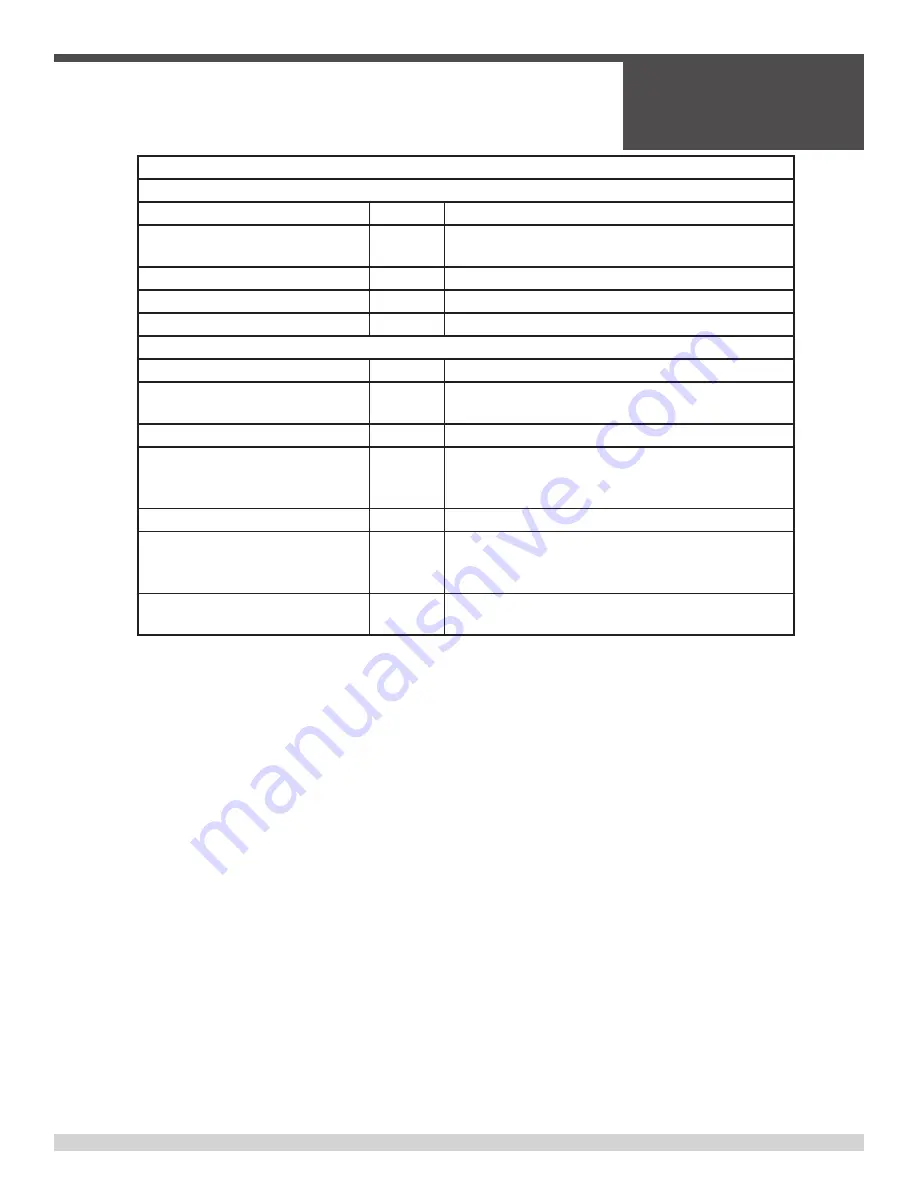

LUBRICATION CHART (cont’d)

EVERY 100 HOURS

LEGS AND TRAVEL BOGIES

Check

Drive Bogie Axle Bearings (4)

Lubricate

NLGI-2 Lithium Base Grease - Lubricate slowly until

excess lubricant is observed.

Bogie Drive Chains (2)

Lubricate

CONTROLLER

Check

Carriage Travel Chains (2)

Lubricate Chain Lube

SEASONAL OR AS REQUIRED

PAVING CARRIAGE

Check

Hydraulic Oil Reservoir (1)

Replace 68 Hydraulic Oil - Remove and clean suction screen.

POWER UNIT

Check

Hydraulic Oil Reservoir (1)

Replace 68 Hydraulic Oil

- Remove and clean suction screen.

Replace oil filter element with a 10 micron element.

LEGS AND TRAVEL BOGIES

Check

Manual Leg Screws (4)

Lubricate

NLGI-2 Lithium Base Grease - Disassemble leg and brush

grease onto leg screw and fill leg thrust bearing with

grease.

Leg Rollers (16)

Lubricate

NLGI-2 Lithium Base Grease - Remove leg rollers and

work grease into bearings.

DAILY ROUTINE SERVICE

1. Check the engine oil level on both power units.

2. Check the battery water level on both power units.

3. Inspect all hydraulic hoses for damage or leaks.

4. IMPORTANT - After each pour, clean the machine as soon as

possible. Coat the paving rollers with light oil.

5. Inspect engine hydraulic pump drive coupling for alignment and

wear.

MACHINE ENGINES

The 4836 Paver uses gasoline engines.

•

Kohler

Gasoline Engines

One engine is mounted on the stationary power unit to power machine

travel and paving carriage travel. The other is mounted on the paving

carriage to power the paving rollers, augers and various optional

carriage accessories. Consult your Engine Owner’s Manual for recom-

mended service procedures.

To insure the best engine performance and life, a strict schedule of

routine service and maintenance is recommended. Change the engine

oil after the first 5 Hours of operation and every 25 Hours thereafter.

•

Kohler

- API Service Classifications SF, SG, SH

Kohler specifies clean, fresh, unleaded gasoline with a pump sticker

octane rating of 87 or higher. In countries using the Research method,

it should be 90 octane minimum. Unleaded gasoline is recommended,

as it leaves fewer combustion chamber deposits. Leaded gasoline may

be used in areas where unleaded is not available and exhaust emis

-

sions are not required. Beware, however, that the cylinder head will

require more frequent service. Gasoline (up to 10% ethyl alcohol, 90%

unleaded gasoline by volume) is approved as a fuel by Kohler engines.

Other gasoline/ alcohol blends are not approved. Methyl Tertiary

Butyl Ether (MTBE) and unleaded gasoline blends (up to a maximum

of 15% MTBE by volume) are approved as a fuel for Kohler engines.

Other gasoline/ether blends are not approved.

IMPORTANT:

Lubricate

pump mounting splines every 500 hours with Dow Corning G-N Metal

Assembly Paste or Dow Corning #77 Assembly Paste.

The engine used on your 4836 Concrete Paver is warranted by the

engine manufacturer. Contact your authorized engine dealer for war-

ranty repair and replacement parts. If there is not an authorized dealer

available, call the ACP Service Department.

SECTION 3

SERVICE

050362

Page 53

3.1 - General Maintenance, continued

Summary of Contents for BDF4836B

Page 5: ...050362 Page 5 Table of Contents continued ...

Page 14: ...050362 Page 14 Notes ...

Page 15: ...SECTION 1 SAFETY 050362 Page 15 SECTION 1 SAFETY ...

Page 21: ...SECTION 1 SAFETY 050362 Page 21 PAGE LEFT BLANK INTENTIONALLY ...

Page 22: ...Notes SECTION 1 SAFETY 050362 Page 22 ...

Page 23: ...SECTION 2 OPERATIONS 050362 Page 23 SECTION 2 OPERATIONS ...

Page 40: ...Power Crown Lever Nut A SECTION 2 OPERATIONS 050362 Page 40 2 6 Power Crown Option ...

Page 46: ...Skew Clamp Skew Cylinder SECTION 2 OPERATIONS 050362 Page 46 2 7 Paving Operations continued ...

Page 49: ...SECTION 2 OPERATIONS 050362 Page 49 PAGE LEFT BLANK INTENTIONALLY ...

Page 50: ...SECTION 2 OPERATIONS 050362 Page 50 Notes ...

Page 51: ...SECTION 3 SERVICE 050362 Page 51 SECTION 3 SERVICE ...