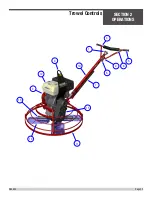

1. Fine Pitch Control Handle

– To adjust the pitch of the blades, turn the handle either clockwise or

counter-clockwise to achieve the desired blade pitch.

2. Handlebar Adjuster

– Change the angle/height of the handle bars by loosening bolts, adjust han-

dlebars to desired location, tighten bolts firmly to hold handlebars in that position.

3. Handle Bar

– When operating the trowel, place both hands on each grip to maneuver the trowel.

4. Recoil Starter Housing

– Automatically spools the recoil starter rope when using to start the

engine.

5. Hand Grip

– Replace hand grips when they become worn or damaged.

6. Centrifugal “Kill” Switch

– In the event the operator loses control of the trowel, this switch will

shut-down the engine.

7. Lifting Tube

- Use this tube to lift the trowel onto a slab. Tube is to be inserted into socket located

in front of the gearbox.

8. Throttle Lever

– Controls engine speed. Returns engine to idle when released.

9. Trowel Lifting Point

– The trowel is equipped with a lifting bail that can be used to safely lift and

move the trowel.

10. Main Tube

- When disassembling components inside the tube exercise caution.

11. Guard Ring

- NEVER! put hands or feet inside guard ring while the machine is running.

12. Engine

– This trowel uses a Honda engine.

13. Trowel Arm – NEVER

operate the trowel with a bent, broken or out of adjustment trowel arm. If the

blades show uneven wear patterns or some blades wear out faster than others, the trowel arm may

need to be adjusted. Use the trowel arm alignment tool P/N 016863 to adjust the trowel arms.

14. Blades

– This trowel is equipped with combination blades. These blades are versatile and should

take care of most troweling needs. In addition, pans can be attached to the trowel arms that will

allow the trowel to float on “wet” concrete.

15. Belt Cover

– (NOTE SHOWN) Remove this cover to gain access to the drive belt.

NEVER

operate the

trowel with this cover removed.

Trowel Controls

SECTION 2

OPERATIONS

064634

Page 34

Summary of Contents for PRO WALK-BEHIND

Page 11: ...Machine Dimensional Specifications 064634 Page 11 GENERAL INFORMATION ...

Page 16: ...Notes 064634 Page 16 GENERAL INFORMATION ...

Page 17: ...SECTION 1 SAFETY SECTION 1 SAFETY 064634 Page 17 ...

Page 18: ...State Regulations SECTION 1 SAFETY 064634 Page 18 ...

Page 19: ...Federal Regulations SECTION 1 SAFETY 064634 Page 19 ...

Page 28: ...Notes SECTION 1 SAFETY 064634 Page 28 ...

Page 29: ...SECTION 2 OPERATIONS SECTION 2 OPERATIONS 064634 Page 29 ...

Page 35: ...2 1 3 4 5 6 7 8 9 10 11 12 13 14 15 Trowel Controls SECTION 2 OPERATIONS 064634 Page 35 ...

Page 38: ...Notes SECTION 2 OPERATIONS 064634 Page 38 ...

Page 39: ...SECTION 3 SERVICE SECTION 3 SERVICE 064634 Page 39 ...

Page 46: ... SECTION 4 PARTS SECTION 4 PARTS 064634 Page 46 ...

Page 47: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 47 ...

Page 52: ...2 8 3 4 5 7 6 11 10 9 1 12 Fine Pitch Assembly Illustration SECTION 4 PARTS 064634 Page 52 ...

Page 99: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 99 ...

Page 105: ......