3.3 Lift Lever Adjustment Procedure

Damage to and/or replacement of a trowel arm can change the adjustment of the lift

lever. This can unbalance the trowel arms and cause the riding trowel to wobble

during operation. To operate smoothly the lift lever on all trowel arms must be

adjusted the same to ensure that the riding trowel is balanced correctly.

Adjusting the trowel arms is accomplished by using the optional trowel arm alignment

jig (Part #: 016863)

. The service manual that is included with the alignment jig

describes in detail the steps to preform this procedure and to check the flatness and

straightness of the trowel arms.

The steps below describe the general procedure to remove the trowel arms to be aligned.

1. Block up pressure plate

[A]

using a wooden block.

2. Remove stabilizer ring from spider assembly (only on available models).

3. Remove blades from trowel arms.

4. Loosen hex head cap screw

[B]

and remove it and the external star washer from the spider boss.

5. Remove trowel arms from spider boss with lift levers in place.

6. Clean flats on trowel arm before placing it in the trowel arm jig (Part #: 016863).

7. Preform the alignment procedures as outlined in the alignment jig service manual (Part #: 047427).

8. Re-attach trowel arm to spider boss and blades to trowel arms.

9. Tighten down hex head cap screw to secure trowel arm in place.

10. Reattach stabilizer ring (only on available models).

Lift Lever Adjustment

Make sure there is NO pitch in the blades

before attempting to remove a trowel arm.

SECTION 3

SERVICE

064634

Page 42

Summary of Contents for PRO WALK-BEHIND

Page 11: ...Machine Dimensional Specifications 064634 Page 11 GENERAL INFORMATION ...

Page 16: ...Notes 064634 Page 16 GENERAL INFORMATION ...

Page 17: ...SECTION 1 SAFETY SECTION 1 SAFETY 064634 Page 17 ...

Page 18: ...State Regulations SECTION 1 SAFETY 064634 Page 18 ...

Page 19: ...Federal Regulations SECTION 1 SAFETY 064634 Page 19 ...

Page 28: ...Notes SECTION 1 SAFETY 064634 Page 28 ...

Page 29: ...SECTION 2 OPERATIONS SECTION 2 OPERATIONS 064634 Page 29 ...

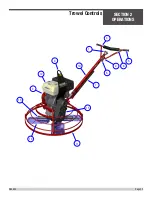

Page 35: ...2 1 3 4 5 6 7 8 9 10 11 12 13 14 15 Trowel Controls SECTION 2 OPERATIONS 064634 Page 35 ...

Page 38: ...Notes SECTION 2 OPERATIONS 064634 Page 38 ...

Page 39: ...SECTION 3 SERVICE SECTION 3 SERVICE 064634 Page 39 ...

Page 46: ... SECTION 4 PARTS SECTION 4 PARTS 064634 Page 46 ...

Page 47: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 47 ...

Page 52: ...2 8 3 4 5 7 6 11 10 9 1 12 Fine Pitch Assembly Illustration SECTION 4 PARTS 064634 Page 52 ...

Page 99: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 99 ...

Page 105: ......