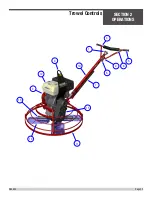

3.4 Trowel Transportation Procedures

Extra care should be taken when lifting the trowel off the ground. Serious damage to the machine or personal injury could

be caused by dropping a trowel.

The trowel is heavy and awkward to move around. Use proper heavy lifting procedures and

DO NOT

lift the trowel by the

guard rings.

The lift bale(

A

) provides an optimal lift point for moving the trowel. A forklift can be used to lift a trowel up onto a building.

Using a crane to move a machine with a lift bale is highly recommended, and is perfectly safe for the machine. Extra care

should be taken when lifting the machine off the ground, however. Serious damage to the machine or personal injury could

be caused by dropping a trowel.

Remove the auxiliary lifting tube(

B

) located on the bottom of the main handle. Insert the tube into the socket(

C

) located

on the opposite side of the gearbox from the handle. Make sure that the hole in the tube engages with the socket. With

one person lifting from the main handle, and another lifting from the auxiliary lifting tube pick up the machine to move it

onto a slab.

The trowel must be stabilized by the person carrying the operator’s handle. If it is not stabilized properly, the handle could

swing around and flip the trowel, causing damage to the trowel and also bodily injury.

A

C

B

Trowel Transportation

SECTION 3

SERVICE

064634

Page 44

Summary of Contents for PRO WALK-BEHIND

Page 11: ...Machine Dimensional Specifications 064634 Page 11 GENERAL INFORMATION ...

Page 16: ...Notes 064634 Page 16 GENERAL INFORMATION ...

Page 17: ...SECTION 1 SAFETY SECTION 1 SAFETY 064634 Page 17 ...

Page 18: ...State Regulations SECTION 1 SAFETY 064634 Page 18 ...

Page 19: ...Federal Regulations SECTION 1 SAFETY 064634 Page 19 ...

Page 28: ...Notes SECTION 1 SAFETY 064634 Page 28 ...

Page 29: ...SECTION 2 OPERATIONS SECTION 2 OPERATIONS 064634 Page 29 ...

Page 35: ...2 1 3 4 5 6 7 8 9 10 11 12 13 14 15 Trowel Controls SECTION 2 OPERATIONS 064634 Page 35 ...

Page 38: ...Notes SECTION 2 OPERATIONS 064634 Page 38 ...

Page 39: ...SECTION 3 SERVICE SECTION 3 SERVICE 064634 Page 39 ...

Page 46: ... SECTION 4 PARTS SECTION 4 PARTS 064634 Page 46 ...

Page 47: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 47 ...

Page 52: ...2 8 3 4 5 7 6 11 10 9 1 12 Fine Pitch Assembly Illustration SECTION 4 PARTS 064634 Page 52 ...

Page 99: ...PAGE LEFT BLANK INTENTIONALLY SECTION 4 PARTS 064634 Page 99 ...

Page 105: ......