41

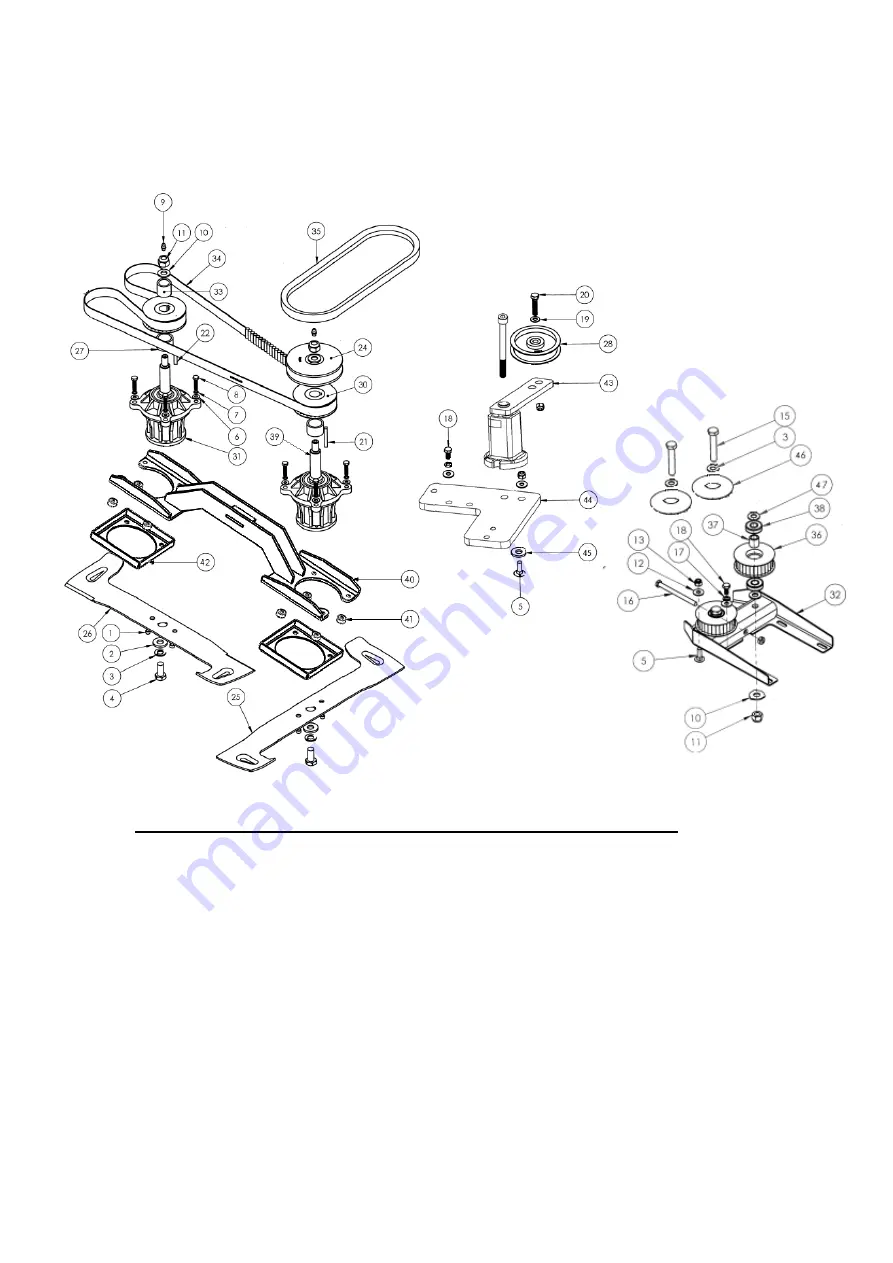

MODEL UPLIFT86:- Spindle/Blade Drive Assembly (Fig 3)

MODEL UPLIFT86:- Spindle/Blade Drive Assembly (Fig 3)

ITEM NO.

DESCRIPTION

PART NUMBER

USED

1

M5x6 SOCKET HD MACHINED

F016J10670

4

2 & 10

HARDENED WASHER M12

W2-M12

6

3

FLAT WASHER M12

WM12

4

4

SET SCREW M12 x 25

SM1225

2

5

M8X25 CUP SQ BOLT

CSM825

3

6

WASHER M6 FORM C

WM6C

8

7

SPRING WASHER M6

SWM6

8

8

SET SCREW M6 x 25

SM625

8

9

GREASE NIPPLE M6

GNM6

2

10 & 2

HARDENED WASHER M12

W2-M12

6

11

NUT M12 NYLOC

NNM12

2

12

M8 FLAT WAHSER FORM C

WM8C

6