© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

802749

Installation

Step 1: Position Washer Near Installation

Area

Move washer as close to the desired area of

installation as possible.

NOTE: For best performance and to minimize

vibration or movement, install washer on a solid,

sturdy and level floor. Some floors may need to be

reinforced, especially on a second floor or over a

basement. Do not install the washer on carpeting,

soft tile, a platform or other weakly supported

structures.

Step 2: Position and Level the Washer

Position washer so it has sufficient clearance for

installation and servicing.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportation of the washer may

cause damage to the dispenser or door.

Place washer in position on a solid, sturdy and level

floor. Installing the washer on any type of carpeting,

soft tile, a platform or other weakly supported

structures is not recommended.

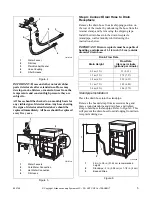

For easier access to leveling legs, prop up washer with

a wooden block. Refer to

Figure 3

.

Place a level on the cabinet top and check if the

washer is level from side to side and front to back.

NOTE: Level must rest on raised portion of top

panel. Refer to

Figure 3

.

If washer is not level, tilt washer to access the front

and rear leveling legs. Loosen the locknuts and adjust

legs by screwing into or out of washer base.

Make sure that the washer does not rock. When

washer is level and does not rock, tighten locknuts

securely against bottom of washer base. If these

locknuts are not tight, washer will move out of

position during operation.

Do not slide washer across floor once the leveling legs

have been extended. Legs and base could become

damaged.

Place rubber feet (supplied in accessories bag) on all

four leveling legs. Refer to

Figure 3

.

Verify that washer does not rock.

Washers elevated above floor level must

be anchored to that elevated surface,

base or platform. The material used to

elevate the washer should also be

anchored to the floor to ensure that the

washer will not walk or that the washer

can not be physically pulled, tipped or

slid from its installed position. Failure to

do so may result in conditions which can

produce serious injury, death and/or

property damage.

W306

WARNING

FLW2290N

1

Level

2

Wood Block

3

Rubber Foot

4

Leveling Leg

5

Locknut

6

Washer Base

Figure 3

FLW229

1

5

3

4

6

2

Summary of Contents for 802749R2

Page 11: ......