12

33711

Section 3 Troubleshooting

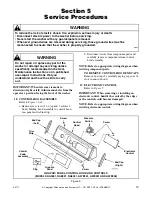

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

10. DRIVE MOTOR OVERLOAD PROTECTOR CYCLES REPEATEDLY

11. OUTER TUB DOES NOT EMPTY

12. EXCESSIVE VIBRATION

POSSIBLE CAUSE

TO CORRECT

Excessive belt tension.

• Adjust belts.

Inoperative motor overload protector.

• Replace motor.

Bind in upper or lower bearing.

• Replace bearing.

Bind in water pump.

• Replace pump.

Bind in transmission.

• Repair or replace transmission.

Brake pads binding.

• Free binding pads, or replace pads.

Incorrect voltage.

• Contact local utility company, or have a qualified

electrician check power supply.

POSSIBLE CAUSE

TO CORRECT

Kinked drain hose.

• Straighten hose.

Drain hose out of clamp in back of cabinet.

• Remove washer front panel and install drain hose into

clamp.

Inoperative water pump.

• Replace pump.

Obstruction in outer tub outlet hose.

• Remove obstruction.

Loosen or broken pump belt.

• Adjust or replace belt.

POSSIBLE CAUSE

TO CORRECT

Unbalanced load in tub.

• Stop washer, redistribute load, then restart washer.

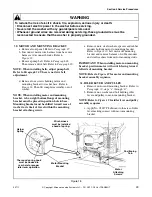

Broken, disconnected or incorrectly adjusted

centering spring(s).

• Connect or replace centering spring(s). Spring should be

located in upper notch. Refer to Figure 9.

Washer is not properly leveled.

• Adjust leveling legs.

Washer is installed on weak, “spongy”, carpeted or

built-up floor.

• Relocate washer, or support floor to eliminate weak or

“spongy” condition.

Incorrect or loose cabinet screws.

• Replace with correct screws or tighten.

Base damaged (washer was dropped).

• Replace base assembly.

Balance ring not positioned properly on

transmission assembly.

• Refer to Paragraph 46.