42

33711

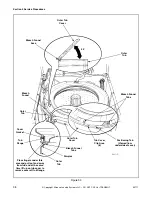

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

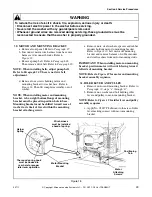

TO INSTALL NO. 495P3 HUB AND SEAL

KIT

IMPORTANT: Be sure inner surface of tub flange is

clean of all foreign material before installing new

seal.

a. Apply a small amount of 27615P Sealant,

(supplied in kit) around outer surface of tub

flange. Refer to Figure 36.

IMPORTANT: DO NOT allow sealant to get in

contact with the flinger, because this could prevent

flinger from keeping moisture out of upper bearing.

Refer to Figure 36.

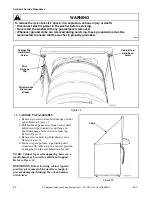

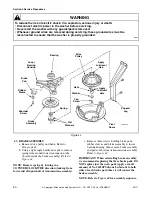

b. Apply a light film of nonstaining petroleum

jelly (such as Vaseline

®

) to bronze portion of

water seal and to outer surface of stainless steel

sleeve. Refer to Figure 37.

IMPORTANT: DO NOT over lubricate!

c. Insert stainless steel sleeve into water seal from

bottom side of the seal until the sleeve is flush

with bronze portion of the seal. Refer to

Figure 37.

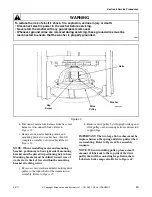

d. Leave the garter spring on seal. Place new seal

over outer tub flange (with seal lip on outside of

tub flange). Then press seal into tub flange

opening using moderate finger pressure.

e. Carefully apply a small amount of No. 27615P

Sealant (supplied with kit) around outer edge of

seal and tub (area located just below garter

spring). Refer to Figure 37.

IMPORTANT: DO NOT allow sealant to contact

sealing surface of water seal because it will cause a

water leak.

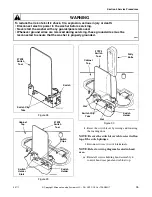

f. Lubricate inner splines of new hub assembly

(supplied in kit) with No. 27604P Anti-Seize

Compound.

g. Carefully place new hub assembly on splined

transmission tube.

IMPORTANT: Firmly push hub down against outer

tub seal and hold in this position.

h. While holding hub down, place spline insert

onto the transmission tube until it bottoms

against the hub. Then place the hex nut on the

transmission tube (with the larger inside bevel

Figure 37

Water

Seal

Lubricate

(Lubricate per

Step “b”)

Lubricate

(Lubricate per

Step “b”)

Stainless

Steel

Sleeve

Bronze Portion

of Seal

Flush

Garter

Spring

Insert Sleeve from

Bottom Side of Seal

Apply Bead of

No. 27615P

Sealant Here

(Step “e”)

Apply Bead of

No. 27615P

Sealant Here

(Step “e”)

Garter

Spring

Press Here

to Assemble