58

33711

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TO REASSEMBLE TRANSMISSION

ASSEMBLY

IMPORTANT: Wash all components in a cleaning

solution (mineral spirits). Wipe inside of

transmission case and cover with a clean cloth,

dampened with cleaning solution, to remove any

impurities. DO NOT allow cleaning solution to come

in contact with bearings and seals in transmission

case and/or cover.

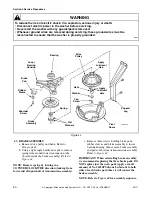

a. Carefully insert output shaft and washer into

transmission case.

b. Place agitator pinion on splines of output shaft

and press onto shaft.

c. Install retainer ring on output shaft.

d. Place transmission case into a vise. Clamp only

the case, not the shaft.

e. Place rack inside transmission case with rack

resting on bar in case. Agitator pinion must

engage the rack.

NOTE: Put a light film of transmission oil on bar

where rack will slide back and forth.

f. Position slide in slot on rack.

NOTE: Put a light film of transmission oil in slot on

rack. Also, transmission oil should be put in the

track of the transmission case where internal gear

will ride.

g. Place internal gear into transmission case.

Make sure guide pin on internal gear fits in hole

on slide.

IMPORTANT: Never install a used internal gear in

a new transmission case. If transmission case and

internal gear are to be reused, be sure they are used

as the original set.

h. Refill transmission case with new No. 27243P

Transmission Oil (one fill).

i. To prevent seal damage, insert input shaft into

cover starting at outer end of cover tube.

IMPORTANT: End of shaft with identification

groove, refer to Figure 46, must be facing outward.

This is the end that will mate with the helix.

j. Install drive pinion, flat washer, lockwasher

and special screw onto input shaft.

NOTE: Use a thread locking compound on threads

of special screw to prevent screw from loosening on

shaft.

IMPORTANT: Make sure mating surfaces of

transmission cover and case are free of oil or any

other foreign material.

k. Place reduction gear on stub shaft of cover and

install screw and washer.

NOTE: Use a thread locking compound on the

threads of the special screw to prevent screw from

loosening on the shaft.

l. Apply a bead of sealant, No. 37577P Loctite, on

mating surface of transmission case.

IMPORTANT: The bead of sealant should be no

more than 1/16 inch in diameter. DO NOT allow any

sealant to contact edges of internal gear (sealer may

damage moving parts).

m. Carefully place transmission cover over top of

transmission case. Make sure holes in cover

line up with holes in case, and marked edges of

two halves are aligned.

n. Carefully lower cover onto case.

o. Secure two transmission halves together, using

eight screws removed during disassembly.

Tighten eight screws evenly.

p. Remove complete transmission assembly from

vise.

q. Apply Anti-Seize Compound, No. 27604P, to

smooth area of both transmission tubes that will

be contacting upper and lower bearings.