26

33711

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

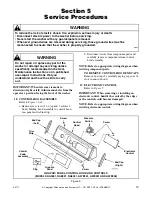

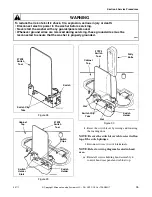

j. Turn the 1/4 inch bolt out of transmission shaft

and remove tool and drive bell from washer.

k. Loosen the two wing nuts and remove drive bell

from tool.

l. Carefully pry the old seal out of the drive bell

and clean any foreign materials from the bell.

IMPORTANT: We recommend that both the seal

seat and the seal head be replaced together in pairs.

DO NOT replace only one of the two.

m. Install the new seal into the drive bell.

n. Remove the seal head from the hub and clean

any foreign material from the hub seal

mounting area.

o. Place the new seal head on hub and carefully

push the seal head into position.

IMPORTANT: Make sure the seal is pressed down

against the shoulder on the hub.

NOTE: Soapy water will aid in the assembly of the

seal onto the hub.

IMPORTANT: DO NOT apply any type of

lubricants to the sealing surfaces of either the seal

seat or seal head as you will damage the seals.

TO REINSTALL DRIVE BELL

a. Position drive bell over transmission shaft.

Rotate drive bell until splines in drive bell line

up with splines on transmission shaft.

b. Place No. 294P4 Bell Tool over top of bell.

Screw bolt into transmission shaft until it

bottoms out.

NOTE: It is not necessary to use the tool jaws on

drive bell during this operation.

c. Use an adjustable wrench and turn large nut on

tool CLOCKWISE to force drive bell down

onto transmission shaft until bell bottoms out

on shaft.

d. Turn bolt out of transmission shaft and remove

tool.

e. Place new “O” ring gasket onto new screw.

Thread the new screw down through hole in top

of drive bell and into transmission shaft. DO

NOT reuse the old screw and “O” ring

gasket!

NOTE: Torque new screw down between 45 to 55

inch pounds (5 to 6.2 Nm). Over torque will

mushroom the plastic bell.

f. Place agitator on top of drive bell. Slowly rotate

agitator until fingers on underside of agitator

line up with large slots on drive bell.

g. A sharp blow on top of agitator, with palm of

your hand, will force agitator down onto drive

bell, allowing fingers on underside of agitator

to lock under bottom edge of drive bell.

NOTE: Do not push agitator onto drive bell any

further than necessary.

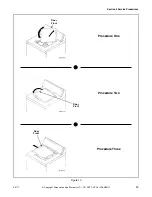

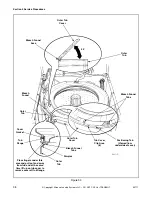

27. FRONT PANEL

Refer to Figure 15.

a. Remove two screws from bottom edge of front

panel.

b. Pull bottom of panel away from washer until

hold-down clips (located on top flange of

panel) disengage from slots in cabinet top.

Hold-Down Clips

Compress hold-down clips enough to remove

them from slots in top flange of panel.

Guide Lugs

Remove screws holding guide lugs to side flanges

of front panel.