33711

51

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

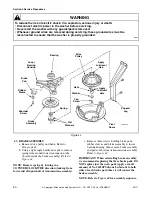

IMPORTANT: When installing spring, be sure it is

inserted into groove in large splines of lower

transmission tube. Use tool, No. 242P4, for installing

the spring.

d. After brake is installed, put the washer through

the following check to make sure the brake is

operating properly.

(1) Turn off the electrical power to the washer.

(2) Turn the drive pulley one complete

revolution in the agitation direction, then

push the drive pulley up against the brake.

(3) Check for a .030 minimum gap between the

drive pulley and the helix ramp surfaces.

IMPORTANT: If the gap is less than .030, the brake

may not stop the washtub from spinning in the

required seven seconds because the brake will not

close properly.

(4) Turn on the electrical power to the washer

and start the washer in the final spin.

NOTE: After the washtub has been spinning for two

minutes, the normal spin speed should be

approximately 580 R.P.M. If not, the cause could be

dragging brake pads. If problems occur with steps 3

or 4, remove the brake assembly and correct the

problem.

44. LOWER BEARING HOUSING

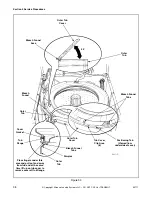

a. Remove two screws from bottom edge of front

panel. Refer to Figure 15.

b. Pull bottom of panel away from washer until

hold-down clips (located on top flange of

panel) disengage from slots in cabinet top.

Refer to Figure 15.

c. Remove two cabinet top hold-down screws and

hinge cabinet top or remove. Refer to

Paragraph 35.

d. Remove agitator. Refer to Paragraph 25.

e. Disconnect filler hose from backflow

preventer. Refer to Figure 31.

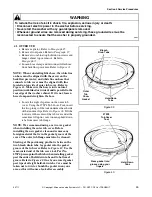

NOTE: When installing filler hose, white line on

hose must be aligned with arrow on backflow

preventer. Refer to Figure 31. White line on hose

that connects to tub cover must be aligned with line

located on top side of outer tub cover. Refer to

Figure 31. Make sure the hose is in its natural

position (not kinked or twisted) and is parallel to the

rear edge of the washer cabinet. If it is not, loosen

hose clamp and straighten the hose.

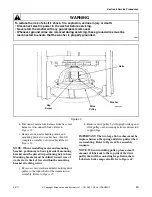

f. Locate the eight clip areas on the outer tub

cover. Refer to Figure 33. Insert your fingers

under this clip area of the cover edge. Refer to

Figure 33. One by one, disengage each clip

from the tub flange by pulling the tub cover

edge out and away from the outer tub and lifting

on the cover at the same time. Do this around

the entire tub cover until the cover is free from

the outer tub flange.

NOTE: When installing outer tub cover, always use

a new cover gasket. The gasket must be inserted into

the bottom of the groove (past the hold-down clips)

in the underside of the tub cover. This may require

using a piece of dowel, wooden pencil or similar

item to push the gasket down past the hold-down

clips.

Wipe or brush the top sealing surface of the outer

tub flange and the sealing surface of the tub cover

assembly and gasket to remove any foreign

materials.

Starting at the bleach funnel area of the tub cover,

place tub cover on outer tub at approximately a 45

degree angle with the position tab on cover fitting

into the tub flange slot. Refer to Figure 33.

Make sure the two bleach funnel outlet tabs are in

the down position and are touching the inside

surface of the outer tub. These tabs can be located

by viewing through the two square holes in the

bleach funnel area of the tub cover. If the bleach

funnel tabs are not down, place a small screwdriver

through the square holes in the bleach funnel area

and push the tabs downward. Refer to Figure 33.