33711

63

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 6

Adjustments

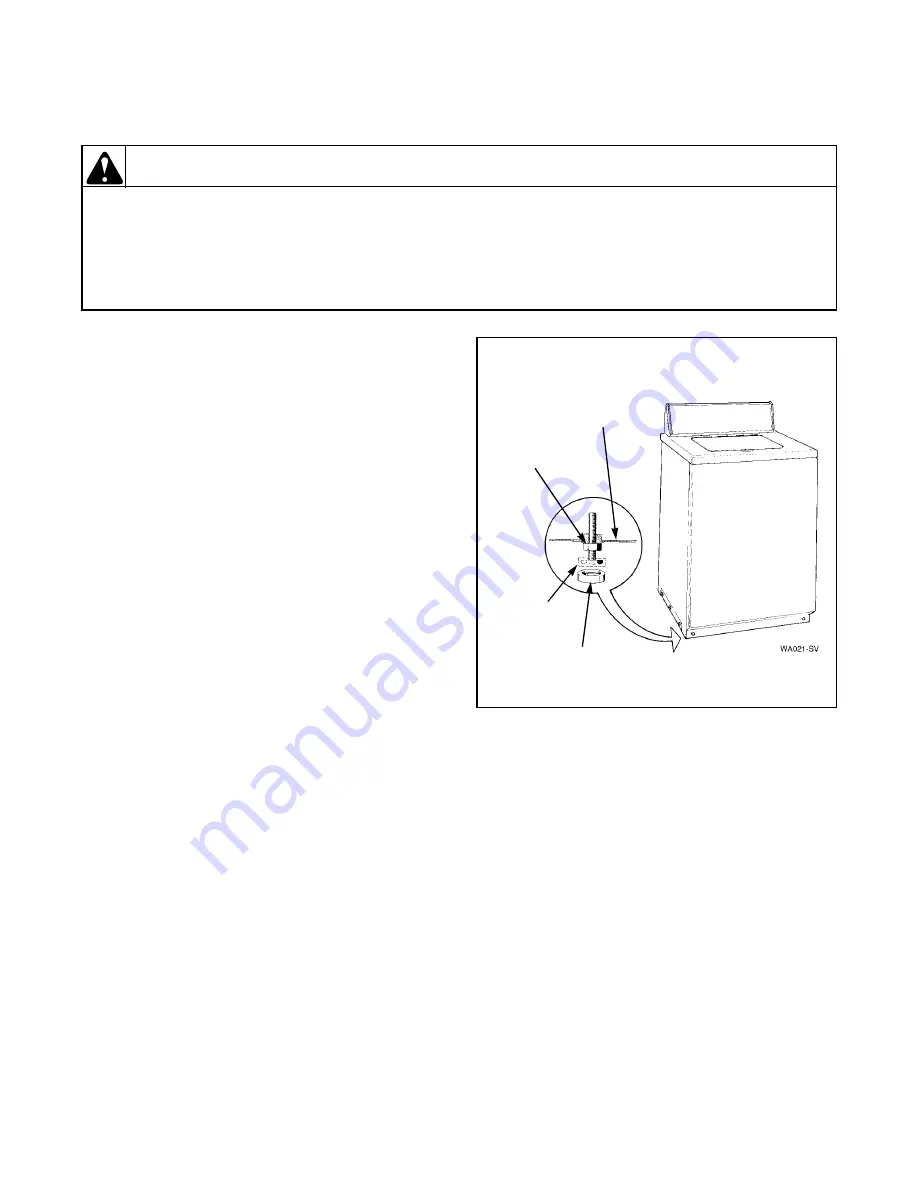

49. LEVELING LEGS

Refer to Figure 52.

IMPORTANT: Select a location, where the washer

is to be installed, with a solid and level floor. DO

NOT install the washer on a weak or spongy floor.

The flexing of a weak floor may cause excessive

vibration. Vibration can also be caused if washer is

installed on carpeting or cushioned vinyl floor.

a. Loosen locknuts and thread leveling legs into

washer base as far as possible.

b. Turn appropriate leveling leg(s) out of base

only until washer is level. Keep washer as close

to floor as possible.

IMPORTANT: All four legs must rest firmly on

floor so weight of washer is evenly distributed.

Washer must not rock. A good test is to place an out-

of-balance load in the washtub, then start washer in

the spin cycle. While washtub is spinning, adjust the

leveling legs accordingly for minimum washer

movement.

c. After the washer has been leveled, tighten

locknuts securely against bottom of washer

base. If locknuts are not tight, the washer will

not stay level during operation.

d. Install rubber cups over leveling legs.

IMPORTANT: DO NOT move washer at any time

unless locknuts are securely tightened and the

shipping brace is in place over the agitator (to

prevent damage to washer components). DO NOT

slide washer across floor once the leveling legs have

been extended, as legs and base could become

damaged.

Figure 52

Washer

Base

Rubber

Cup

Leveling

Leg

Locknut