64

33711

Section 6 Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

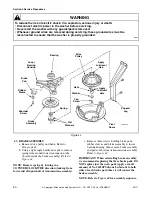

50. PRESSURE SWITCH

Refer to Figure 53.

NOTE: DO NOT ADJUST PRESSURE SWITCH

IF WASHER IS WITHIN THE WARRANTY

PERIOD.

The pressure switch on pressure-fill automatic washers

is set at the factory for proper water fill levels.

However, if there is a problem of overfilling or

underfilling, the pressure switch can be adjusted.

The maximum water fill level can be increased by

turning adjusting screw CLOCKWISE, and decreased

by turning screw COUNTERCLOCKWISE.

One quarter turn of the adjusting screw represents

approximately one inch (2.54 cm) increase or decrease

of water level in washtub.

IMPORTANT: DO NOT turn adjusting screw more

than 3/4 of a turn in either direction as the switch

may be damaged and flooding could result.

51. BELT (Agitate And Spin)

No belt adjustment is required.

NOTE: After placing the motor and mounting

bracket in the washer, start the four hold-down

screws, but do not tighten them at this time. Pivot

the left side of the mounting bracket as far back as

it will go, then tighten the four screws. This

mounting bracket adjustment is necessary to ensure

the proper belt drive action.

52. BELT (Pump)

NOTE: Adjustment must be made after motor has

been properly positioned. Refer to Paragraph 51.

a. Remove front panel. Refer to Paragraph 27.

b. Loosen the two front mounting screws, then

loosen the rear screw. Refer to Figure 54.

Figure 53

Adjusting

Screw

Adjusting

Screw

Rotary Pressure Switch

Slide Pressure Switch

Figure 54

Pump

Attaching

Screws

Pump

Belt