© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

9001909

24

Electrical Installation

IMPORTANT: Electrical ratings are subject to

change. Refer to serial decal for electrical ratings

information specific to your machine.

IMPORTANT: Alliance Laundry Systems

warranty does not cover compounds that fail as a

result of improper input voltage.

The AC inverter drive requires a clean power supply

free from voltage spikes and surges. A voltage monitor

should be used to check incoming power. The

customer’s local power company may provide such a

monitor.

If input voltage measures above 240V for a 220V

drive or above 415V for a 400V drive, ask the power

company to lower the voltage. As an alternative, a

step-down transformer kit is available from the

distributor.

The AC drive provides overload protection for the

drive motor. However, a separate single or three phase

circuit breaker must be installed for complete

electrical overload protection. This prevents damage

to the motor by disconnecting all legs if one should be

lost accidentally. Check the data plate on the back of

the washer-extractor or consult

for circuit

breaker requirements.

The washer-extractor should be connected to an

individual branch circuit not shared with lighting or

other equipment.

The connection should be shielded in a liquid tight or

approved flexible conduit with proper conductors of

correct size installed in accordance with the National

Electric Code or other applicable codes. The

connection must be made by a qualified electrician

using the wiring diagram provided with the washer-

extractor, or according to accepted European standards

for CE-approved equipment.

Use wire sizes indicated in

50 feet.

Use next larger size for runs of 50 to 100 feet. Use two

sizes larger for runs greater than 100 feet.

For personal safety and proper operation, the washer-

extractor must be grounded in accordance with state

and local codes. If such codes are not available,

grounding must conform with the National Electric

Code, article 250-95. The ground connection must be

made to a proven earth ground, not to conduit or water

pipes.

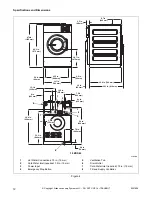

Electrical Connection

Figure 16

Remove the cover plate at the back of the machine.

Connect the power cable to the connectors using

copper conductors only.

Machine without Electric Heating

Connect 200-240V single phase (1AC) to the

connectors “N” and “L1”. The green/yellow

grounding clamp has to be the grounding wire “PE”.

Hazardous Voltage. Can cause shock,

burn or cause death. Allow machine

power to remain off for two minutes prior

to working in and around AC inverter

drive.

W359

WARNING

Hazardous Voltage. Can cause shock,

burn or death. Verify that a ground wire

from a proven earth ground is connected

to the lug near the input power block on

this machine.

W360

WARNING

Do not use a phase adder on any variable-

speed machine.

W490

DANGER

CFD28N

PE

L3

L2

L1

N

4A

3 K 380V + N

3 K 220V

220V

Summary of Contents for CFD14C

Page 2: ......