Installation

27

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Machine Anchoring

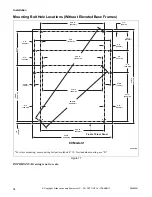

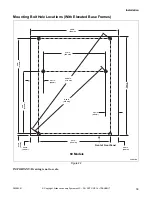

Before anchoring the machine, refer to

Table 1

to

determine the appropriate method of anchoring for the

machine.

NOTE: Improper installation may void the

warranty. Consult the manufacturer or distributor

before varying from a procedure.

Direct-to-Finished-Floor Installation

Installing With Expansion Bolts for

2 Speed Models

NOTE: Expansion bolts are not suitable for

variable-speed machine installations.

1. Verify the floor meets the requirements given in

the

Machine Foundation

section.

2. Mounting surface should be level and machine

must be properly grouted.

3. Use the base of the machine as a template by

positioning the machine in the desired location

and marking the pre-drilled mounting holes on

the floor. Mounting Bolt templates are available

through Alliance Laundry Systems.

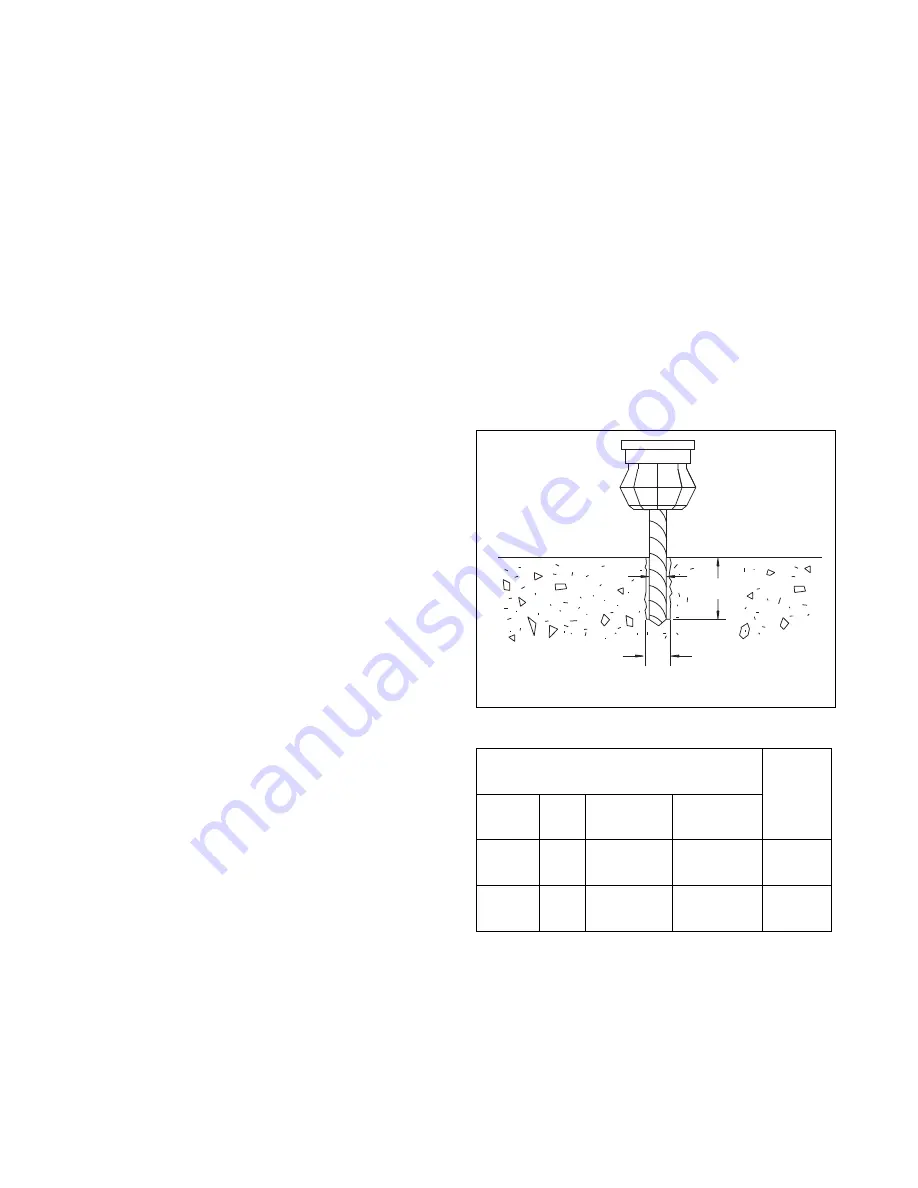

4. Refer to

Figure 9

and

Table 4

to set the drill

depth gauge.

5. Drill the holes to the set depth. Refer to

Table 4

.

6. Use compressed air or a squeeze bulb to clean out

debris from each hole.

7. Fill half the hole depth with an industry-accepted

adhesive anchoring system.

8. Insert expansion bolt until it reaches the bottom

of the hole and 1.5 inches (38 mm) of the bolt

extends above the surface.

9. Allow adhesive around bolt to cure properly.

NOTE: Select the proper size and strength anchor

system. Follow the manufacturer’s installation

instructions and recommended cure times.

10. Position machine over anchoring bolts.

11. Raise and level the machine .5 inch (13 mm) off

the floor on three points, using spacers such as

nut fasteners.

12. Fill the space between the machine base and the

floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

13. Position washers and nuts on bolts and finger

tighten nuts to machine base.

14. Before grout sets completely, make a drain

opening in the grouting at the rear center of the

machine with a stiff piece of wire. This opening

should be approximately .5 inch (13 mm) wide to

allow any surface water build-up under the base

of the machine to drain away.

Do not omit this

step.

15. Allow machine grout to set, but not cure.

16. Remove the spacers carefully, allowing the

machine to settle into the grout.

17. Tighten the nuts by even increments – one after

the other using the specified torque – until all are

tightened evenly and the machine is fastened

securely to the floor. Refer to

Table 4

.

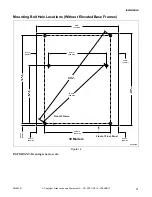

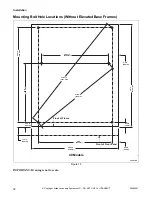

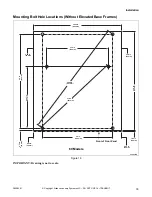

Figure 9

CHM2285N

Anchor Specifications

(refer to

Figure 9

)

Torque

(ft.- lbs.)

Models

A

B

(minimum)

C

20-60

5/8

in.

2.75 in.

(69.9 mm)

.625 in.

(15.9 mm)

90

(ft.-lbs.)

80-125 3/4

in.

3.25 in.

(82.6 mm)

.75 in.

(19 mm)

175

(ft.-lbs.)

Table 4

CHM

B

C

A

Summary of Contents for CHM1772C

Page 2: ......