Maintenance

User-Maintenance Instructions

Cold Weather Care

If the unit is delivered on a cold day (below freezing), or is stored

in an unheated room or area during the cold months, do not at-

tempt to operate the washer until it has had a chance to warm up.

Water from the previous cycle may remain.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the control panel.

Some cleaning products may harm the finish on the control panel

or damage the interior. DO NOT use products that contain alco-

hol on the control panel. Wipe the panel dry after cleaning.

Wipe the washer cabinet as needed. If detergent, bleach or other

washing products are spilled on the cabinet, wipe immediately.

Some products will cause permanent damage if spilled on the

cabinet.

Do not use scouring pads or abrasive cleansers on control panel

or cabinet.

The washtub will need no particular care though it may need rins-

ing or wiping after some unusual loads have been washed. This

also may be necessary if too little detergent has been used.

Leave the lid open to allow the inside of the washer to dry out

after use. This helps prevent musty odors from developing.

The agitator should not be removed except for service. The wash-

tub is designed to be self cleaning.

Replacing Hoses

Hoses and other rubber parts deteriorate after extended use. Ho-

ses may develop cracks, blisters or material wear from the tem-

perature and constant high pressure they are subjected to.

All hoses should be checked on a monthly basis for any visible

signs of deterioration. Any hose showing the signs of deteriora-

tion listed above should be replaced immediately. All hoses

should be replaced every five years.

Filter Screens

Check the filter screens in the fill hoses for debris or damage ev-

ery six months. Clean or replace them if necessary.

If the washer is filling with water slower than normal, check the

filter screens. Clean or replace them if necessary.

Order filter screen Part No. 803615 from the nearest authorized

parts distributor.

Reinstallation of Shipping Materials

You must install the shipping brace and shipping plug any time

the washer is moved.

Shipping Brace

The shipping brace in the lid opening should be saved and rein-

stalled whenever the washer is moved. To reinstall the brace,

open the washer lid and place the brace over the washer agitator,

placing the back of the brace into the lid opening first.

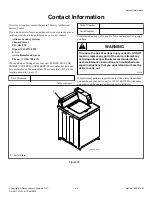

Shipping Plug

The plastic shipping plug should be saved and reinstalled any

time the washer is moved. The plug fits into two openings: The

base opening and the shipping plug opening on the bottom of the

movable pivot dome. The plug MUST be inserted into both open-

ings to prevent damage to the washer. In order to accomplish this,

the shipping plug opening must be directly lined up with the base

opening.

.

TLW2103N_SVG

2

1

4

3

1.

Shipping Plug Opening

2.

Base Opening

3.

Shipping Plug

4.

Shipping Brace

Figure 24

Motor Overload Protector

The internal overload protector will stop the motor automatically

in the event of an overload.

The overload protector will reset itself in two or three minutes

and the motor will restart automatically.

Maintenance

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

24

Part No. 205161EN

Summary of Contents for CTLW-35A

Page 2: ......