232

800170

Section 7 Dryer Test Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer/dryer before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start the washer/dryer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer/dryer is properly grounded.

W014R1

WARNING

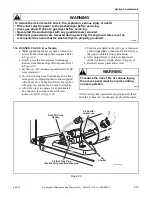

144. SENSOR CHECK (Gas Models)

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to

.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel.

c. Close main gas shut-off valve. Refer to

.

d. Remove wires from sensor terminals. Refer to

.

e. Set test meter to read Ohms and put meter

probes on sensor terminals. Meter should read

“zero” Ohms. If meter registers an Ohm reading

of any amount, replace sensor.

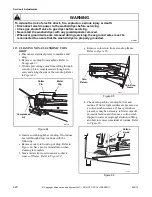

145. IGNITER CHECK (Gas Models)

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to

.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel. Refer

to

.

c. Close main gas shut-off valve. Refer to

.

d. Disconnect igniter wires at disconnect block.

e. Set test meter to read Ohms and put meter

probes on terminals of igniter wires.

f.

Silicon Carbide Igniter

– meter should read

between 45 – 200 Ohms. Refer to

NOTE: If meter does not read appropriate Ohms,

then replace the igniter.

IMPORTANT: Always examine all wires, terminals

and connectors to be sure wiring is correct before

replacing any components.

Figure 99

SILICON CARBIDE IGNITER AND

BRACKET ASSEMBLY

D337SE3A

Igniter and

Bracket

Attaching

Screw

White

Ceramic

Portion