801805

79

Section 5 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

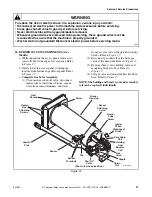

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

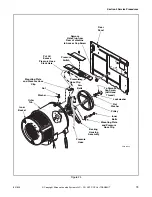

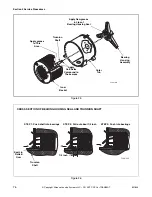

IMPORTANT: When installing inner basket, the

following steps must be taken to ensure that the seal

is properly orientated:

c. Install inner basket assembly by pushing all the

way into outer tub. Refer to Figure 26, Step 1.

d. Slightly pull out inner basket about 1/4 inch to

ensure that the bearing housing seal lips are not

rolled over. Refer to Figure 26, Step 2.

NOTE: If inner basket is pulled out more than 3/8

inch (past step on trunnion shaft), repeat Steps “c”

and “d”.

e. Fully reseat inner basket. Refer to Figure 26,

Step 3.

f. Install pulley and cap screw. Be careful not to

push the shaft forward while tightening the

screw.

IMPORTANT: When installing pulley, always use a

new cap screw to prevent screw from loosening

during operation. Use a thread tap to clean old

Loctite out of pulley screw receiving hole before

installing new screw. This ensures that inner basket

and pulley properly seat.

NOTE: When installing new cap screw, apply a

thread locking compound to screw threads and

torque new cap screw to 240 minimum to 260

maximum inch pounds (27.5 to 29.7 Nm).

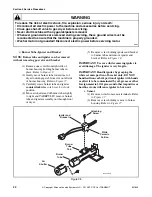

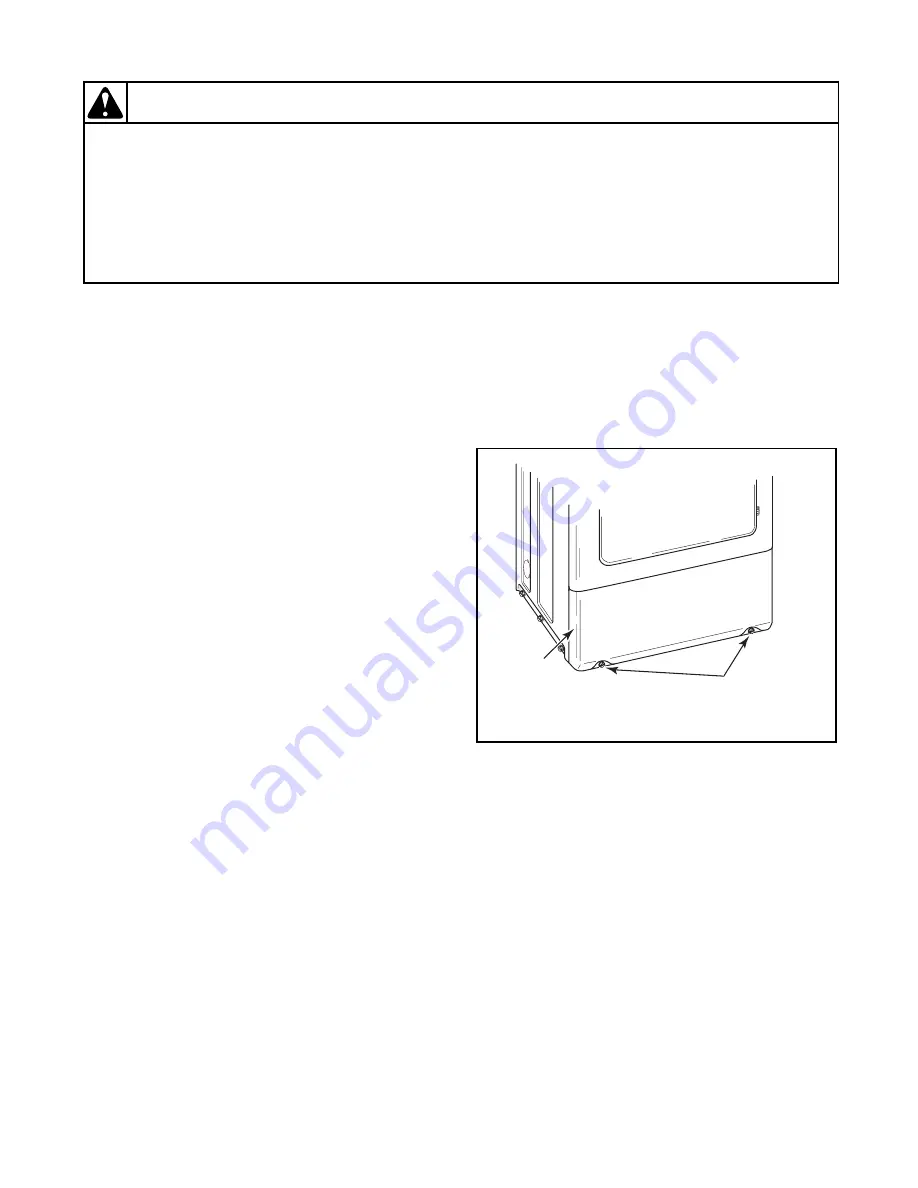

53. DRYER ACCESS PANEL

Refer to Figure 27.

a. While supporting access panel, remove two

screws from bottom edge of panel.

b. Gently lower access panel to disengage panel

locators from bottom edge of front panel.

c. Remove access panel.

Figure 27

Access

Panel

Panel

Attaching

Screws

D302SE3B