© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

9001909

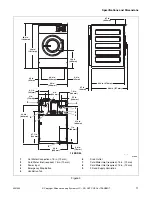

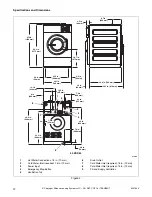

Installation

Dimensional Clearances

shows recommended minimum clearances on

all sides of the washer-extractor.

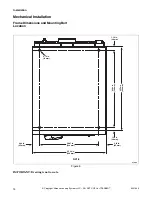

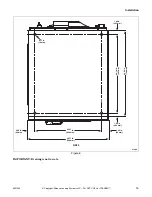

Machine Foundation

Thoroughness of detail must be stressed with all

foundation work to ensure a stable unit installation,

eliminating possibilities of excessive vibration during

extract.

The washer-extractor must be placed on a smooth level

surface so that the entire base of the machine is

supported and rests on the mounting surface.

The standard installation does not require anchoring

unless mandated by state or local codes.

Kinetic energy of the cylinder and dynamic loads on

the floor or foundation are shown in

can be used as a reference when designing

floors and foundations.

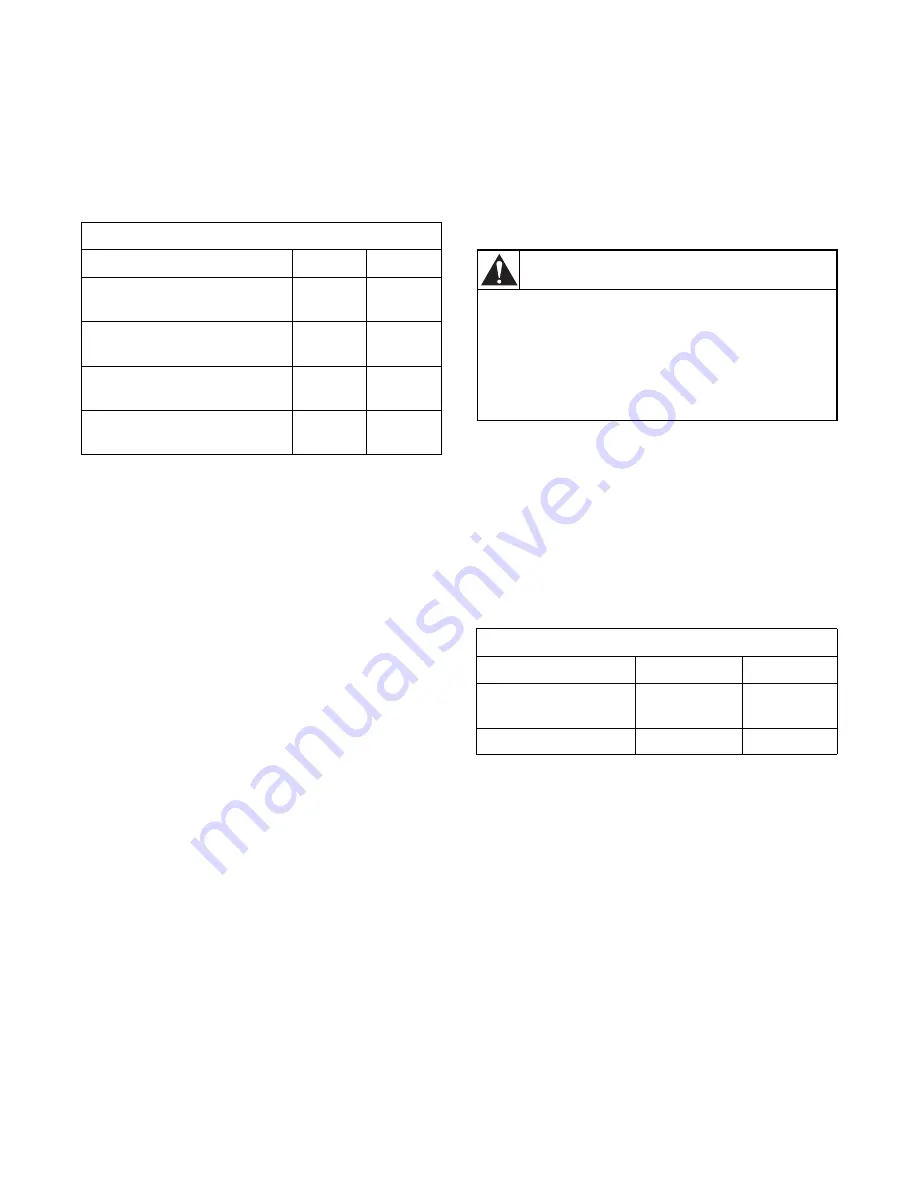

Recommended Minimum Clearances

Model

18

30

Minimum rear clearance

24 in.

(600 mm)

24 in.

(600 mm)

Minimum clearance between

machine and wall

6 in.

(150 mm)

6 in.

(150 mm)

Minimum clearance between

machines (side)

1 in.

(25.4 mm)

1 in.

(25.4 mm)

Minimum front clearance

(door swing)

16.5 in.

(419 mm)

16.5 in.

(419 mm)

Table 1

Floor Load Data

Model

18

30

Kinetic energy of the

cylinder

1386 N/m

2592 N/m

Dynamic bottom load

700 N/16 Hz

1000 N/16 Hz

Table 2

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

W488

CAUTION

Summary of Contents for NX18BVPA6

Page 2: ......