Installation

11

F232158

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

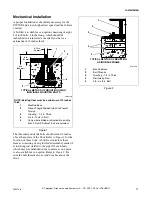

Mechanical Installation

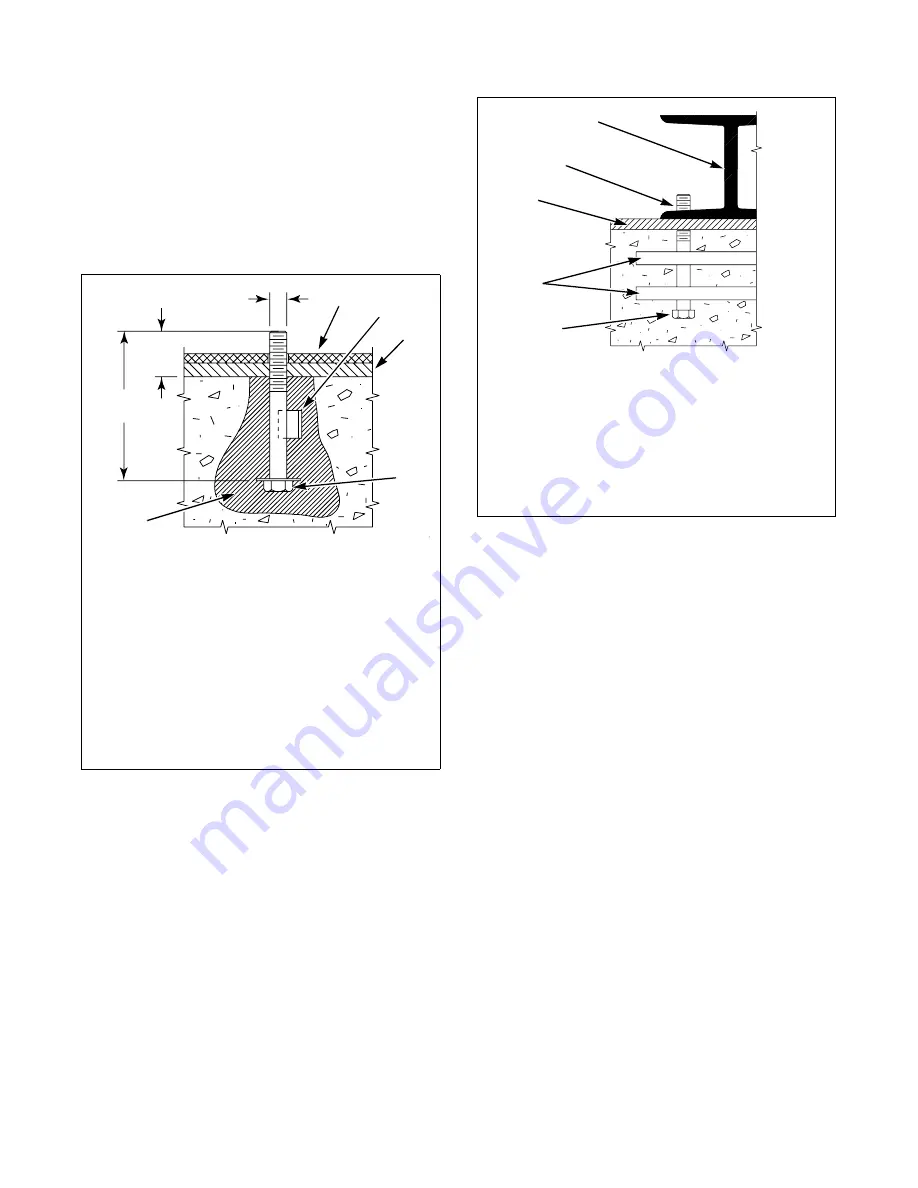

A proper foundation is absolutely necessary for the

UW50P-4 due to its high extract speed and the G-force

exerted.

A bolt kit is available as an option consisting of eight

3/4 inch bolts, 8 inches long, which should be

imbedded in a reinforced concrete floor that is a

minimum of 12 inches thick.

Figure 1

Figure 2

The threaded end of the bolts should extend 2 inches

above the surface of the floor. Refer to

Figure 3

for the

location of these bolts. A bolt locator fixture (base

frame), consisting of a rigid welded assembly made of

reinforcing rod welded to the eight 3/4 inch bolts

which may be embedded in the concrete as one piece

is also available as an option. Refer to

Figure 2

. Be

sure the bolt threads also extend 2 inches above the

floor.

PHM178N

NOTE: Existing floor must be a minimum of 12 inches

thick.

1

Machine Base

2

Piece of Angle Welded to Bolt to Prevent

Turning

3

Grouting – 1/2 in. Thick

4

3/4 in.-10 x 8 in. Bolt

5

Conical hole drilled or chiseled into existing

floor. Fill with “Sulfaset” bolt or equivalent.

0.75 in.

(19 mm)

2 in.

(51 mm)

8 in.

(203 mm)

4

1

TYPICAL METHOD OF MOUNTING USING

INDIVIDUAL MOUNTING BOLTS

2

5

3

PHM179N

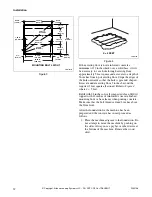

1

Machine Base

2

Bolt Threads

3

Grouting – 1/2 in. Thick

4

Reinforcing Rod

5

3/4 in. x 8 in. Bolt

PHM179N

1

2

3

4

TYPICAL METHOD OF MOUNTING

USING BASE FRAME

5