© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Specifications and Dimensions

F8138601

32

To connect water service to machine with rubber

hoses, use the following procedure:

1. Before installing hoses, flush the water system

for at least two minutes.

2. Check filters in the washer-extractor’s inlet hoses

for proper fit and cleanliness before connecting.

3. Hang the hoses in a large loop; do not allow them

to kink.

If additional hose lengths are needed, use flexible

hoses with screen filters. Each hose should have a

screen filter installed to keep rust and other foreign

particles out of the water inlet valves.

Pressure of 30 – 85 psi (2 – 5.7 bar) provides best

performance. Although the washer-extractor will

function properly at lower pressures, increased fill

times will occur.

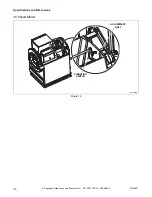

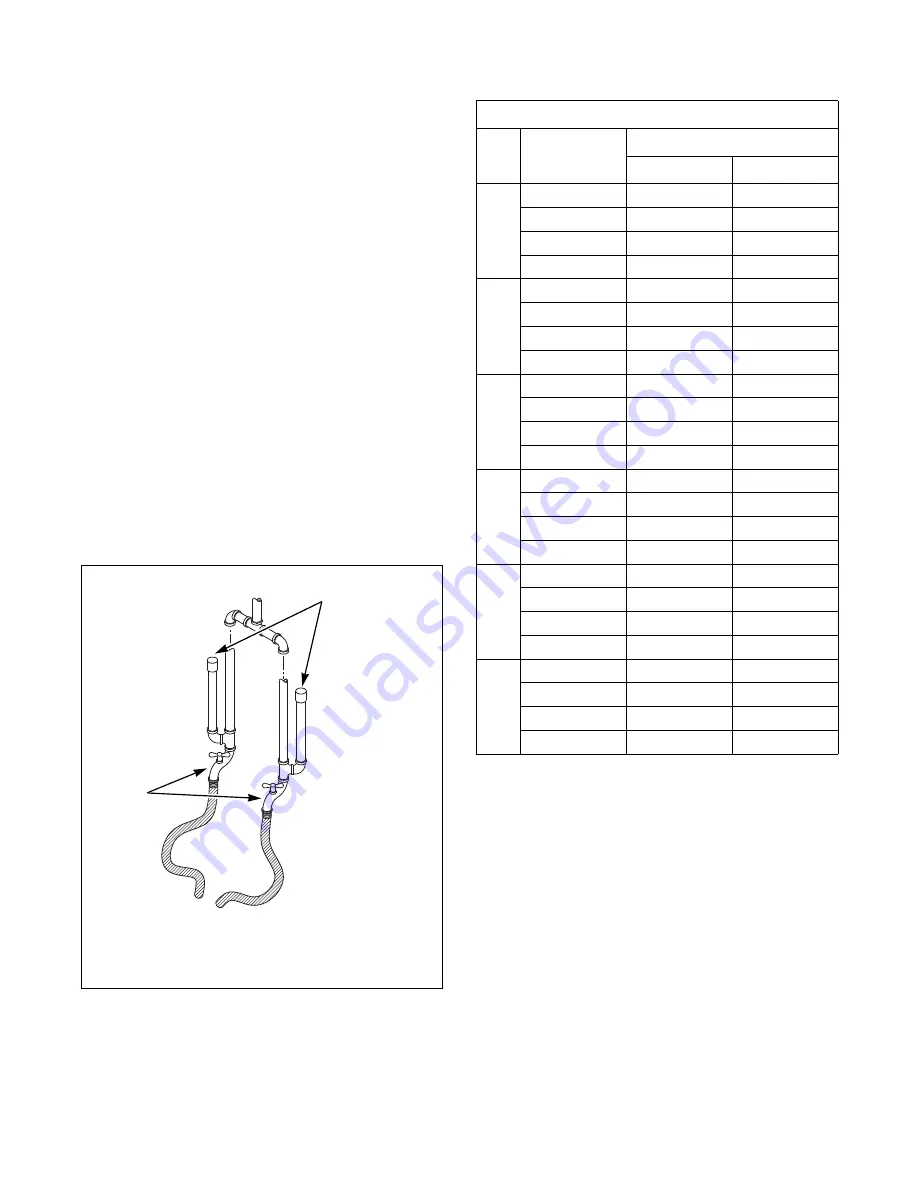

Suitable air cushions should be installed in supply

lines to prevent “hammering.” Refer to

Figure 19

.

For machines labeled with the CE mark, backsiphon

protection devices must be installed previous of all

machine water inlet valves in accordance with

accepted European standards.

Figure 19

P038I

1

Air Cushions (Risers)

2

Water Supply Faucets

P0

38

I

1

2

Water Supply Line Sizing

M

ode

l

Number

of Machines

Supply Line Size, in. (mm)

Main

Hot/Cold

35

1

1 (25)

0.75 (19)

2

1.5 (38)

1 (25)

3

2 (50)

1.25 (32)

4

2 (50)

1.5 (38)

60

1

1.25 (32)

1 (25)

2

2 (50)

1.25 (32)

3

2 (50)

1.5 (38)

4

2.5 (64)

2 (50)

80

1

1.25 (32)

1 (25)

2

2 (50)

1.25 (32)

3

2 (50)

1.5 (38)

4

2.5 (64)

2 (50)

100

1

1.5 (38)

1 (25)

2

2 (50)

1.5 (38)

3

2 (50)

1.5 (38)

4

2.5 (64)

2 (50)

125

1

2 (50)

1.25 (32)

2

2.5 (64)

2 (50)

3

2.5 (64)

2 (50)

4

2.5 (64)

2.5 (64)

150

1

2 (50)

1.25 (32)

2

2.5 (64)

2 (50)

3

2.5 (64)

2 (50)

4

2.5 (64)

2.5 (64)

Table 6