Supply Cable

• Conductors with copper cores (For wire size details, refer to

Electrical Specifications - Models Outside of North America

or

Electrical Specifications - North American Models

)

• Stranded conductors (flexible wiring) that can withstand vi-

bration from machine

• For crossection size, refer to

• Route the supply cable as short as possible, directly from the

supply protection device to the washer without branching off

• Do not use a plug or extensions cords (the machine is inten-

ded to be permanently connected to the electrical network)

Determining AWG Sizes

Power supply protection device nominal current

Min. phase conductor

section, AWG [mm

2

]

Min. protection conduc-

tor section, AWG [mm

2

]

Automatic circuit break-

ers

Fuses

16A (15A)

10A (10A)

15 [1.5]

15 [1.5]

20A (20A)

16A (15A)

13 [2.5]

13 [2.5]

25A (-)

20A (20A)

11 [4]

11 [4]

40A (40A)

32A (30A)

9 [6]

9 [6]

63A (-)

50A (50A)

7 [10]

7 [10]

80A

63A

5 [16]

5 [16]

100A

80A

3 [25]

5 [16]

125A

100A

2 [35]

3 [25]

Table 16

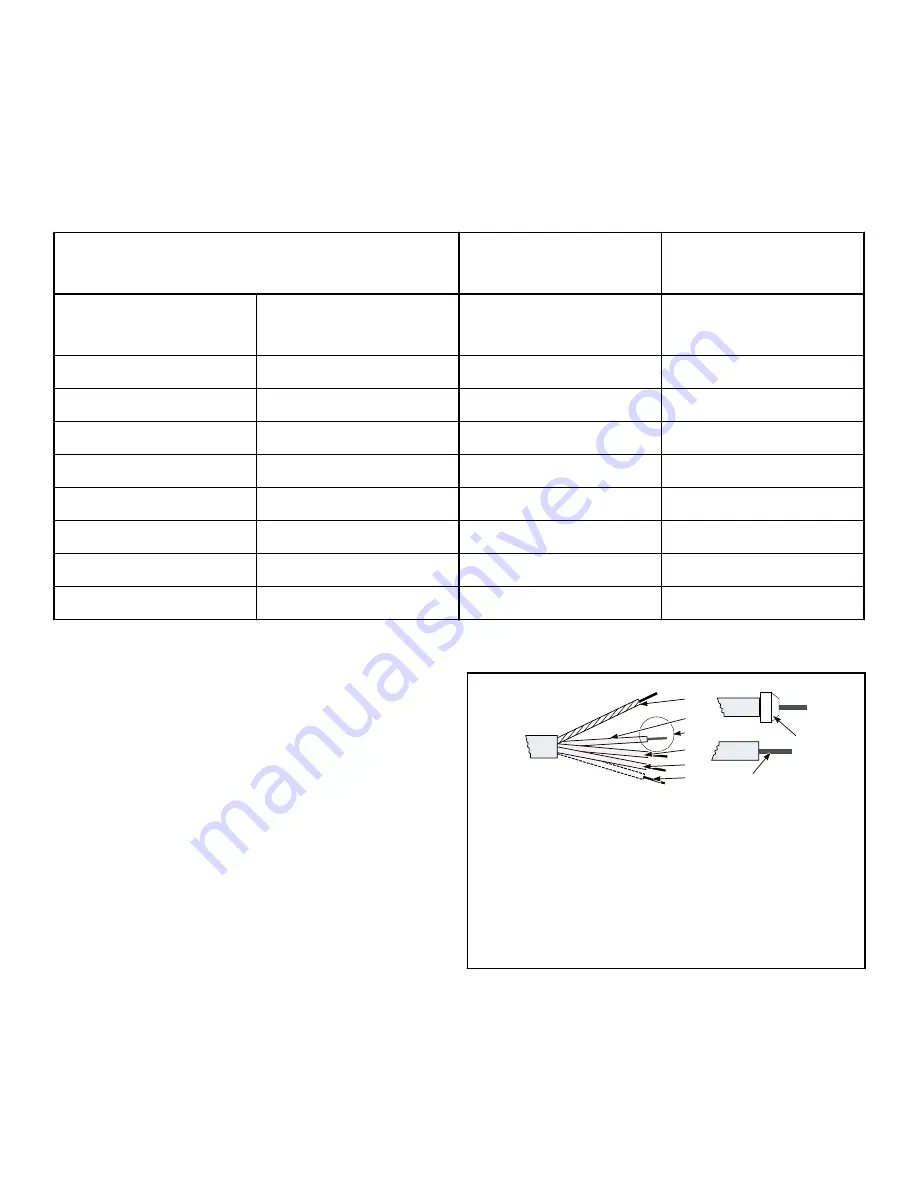

To connect the supply cable, the following steps must be per-

formed:

1. Insert cable through opening on rear panel. Insure a strain re-

lief is used so the supply cable can not move.

2. Strip the conductor ends. Refer to

. The protection

conductor must be longer so it can be routed to the machine

without tension.

CHM2487N_SVG

7

6

5

4

3

2

1

1.

Protection conductor

2.

Phase conductor

3.

Phase conductor

4.

Phase conductor

5.

Neutral conductor

6.

Molded tube

7.

Stripped length of conductors

Figure 29

3. With stranded conductors, use wire end tubes with an insula-

ted sleeve (6) for L1/U, (L2/V), (L3/W), (N) conductors.

Make sure there is no accidental contact, since the supply ca-

ble stays under voltage even when the main switch is off.

Installation

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

45

Part No. D1598ENR10

Summary of Contents for UY105 PRO

Page 2: ......