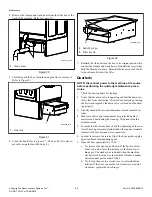

1.

Bracket

2.

Steam hose

3.

Cable

4.

Steam coil

Figure 39

3. Connect steam hose to steam valve.

4. Connect the cable to the steam coil.

5. Fit rear cover back to its original place.

Supply Dispensing

WARNING

Dangerous Chemicals. May damage eyes and skin.

Wear eye and hand protection when handling chemi-

cals; always avoid direct contact with raw chemicals.

Read the manufacturer’s directions for accidental

contact before handling chemicals. Ensure an eye-

rinse facility and an emergency shower are within

easy reach. Check at regular intervals for chemical

leaks.

W363

Supply Dispensing

Number of external liquid supply connections

8

Liquid supply connection size, in. [mm]

5/16 [8]

Number of diluted liquid soap supply connec-

tions

3

Diluted liquid soap supply connection size, in.

[mm]

1/2 [12]

Table 36

IMPORTANT: Always use liquid soap pumps with a

flow that bring the requested quantity in less than 30

sec.

IMPORTANT: Start pumping immediately after water

valves are open. The incoming water dilutes the liquid

soap and brings it into the tub assembly.

Secure the location of the wiring and hoses so they can not be

pinched, damaged or rubbed. Before you start to use liquid soap,

check with your liquid soap supplier whether the liquid soap is

harmless and inert to PP and PVC material in order to avoid dam-

age to machine.

IMPORTANT: Failure to follow these instructions could

damage the machine and void the warranty.

Connection of External Liquid Supplies

1. Facing the rear of the machine, locate the eight (8) 5/16 inch

[8 mm] supply hose connections found on the left-hand side

of the valve panel. Refer to

.

NOTE: Recommended setting of the pump's flow

rate is 60 to 100 liters per hour.

Installation

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

60

Part No. D1598ENR10

Summary of Contents for UY105 PRO

Page 2: ......