1.

Top of Motor Switch

2.

Thermal Overload Protector

3.

Plastic Clip

4.

Motor Switch

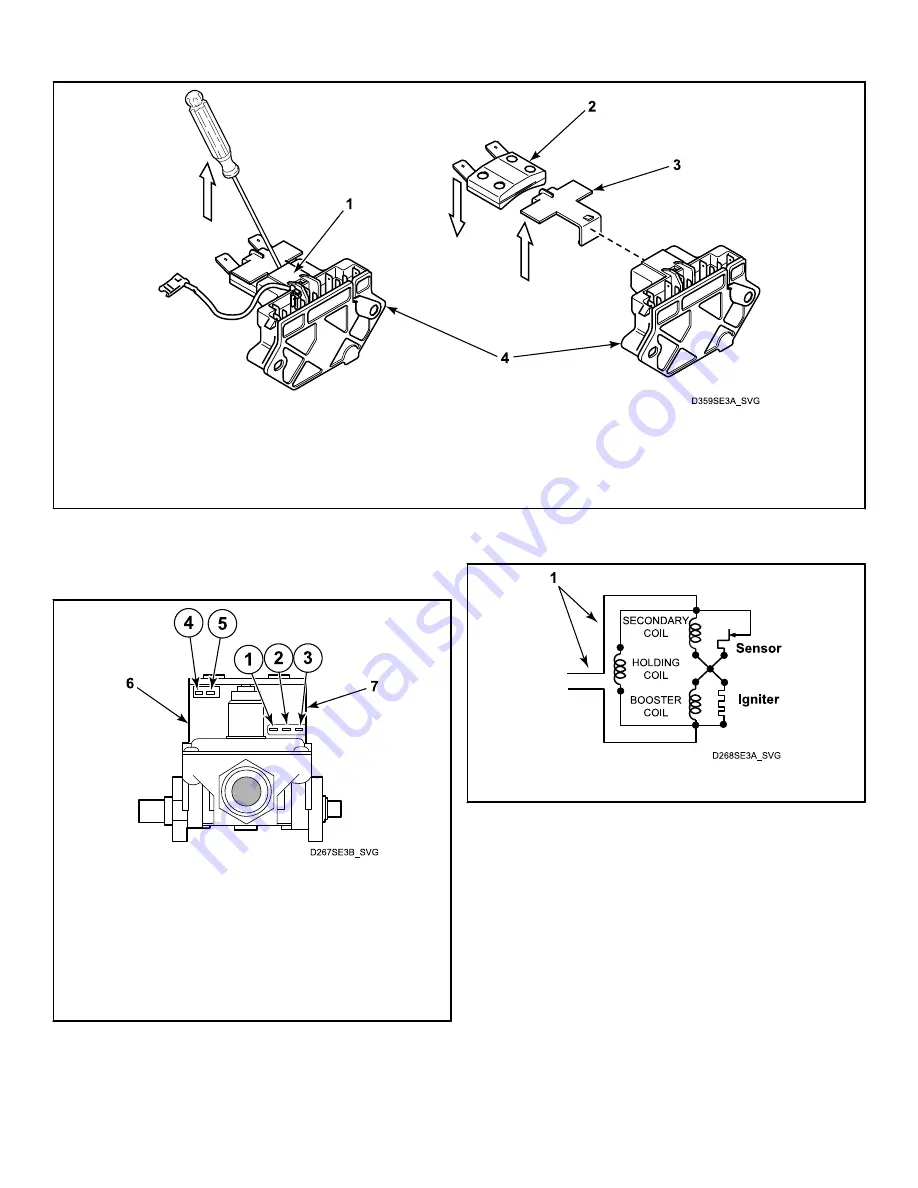

Figure 14

Burner System Operation - Gas Models

1.

Terminal 1

2.

Terminal 2

3.

Terminal 3

4.

Terminal 4

5.

Terminal 5

6.

Secondary Coil

7.

Holding Coil and Booster Coil (Split Coil Valve)

Figure 15

1.

120 Volt, 60 Hertz Electrical Supply Line

Figure 16

Gas Models

and

.

1.

Components.

This burner has four basic components: a sili-

con carbide (glow bar) igniter, burner tube, sensor, and a two-

stage gas valve consisting of a split-coil valve and a secon-

dary coil valve. The split-coil valve is opened when the dryer

thermostat calls for heat, while the secondary valve does not

open until the igniter has attained ignition temperature.

2.

Pre-Ignition Circuits.

When the dryer thermostat calls for

heat, circuits are completed through the holding coil, sensor,

booster coil and igniter. Both coils must be energized to open

the split-coil valve. Once opened, the holding coil can hold

the valve open without assistance from the booster coil. The

sensor triggers the current to travel around the secondary coil

and through the igniter, causing the igniter to get hot.

Test Procedures

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

59

Part No. D515519R3

Summary of Contents for BD3NGBGS303EW01

Page 2: ......